Mekalite leads the way in transforming manufacturing precision with our top-notch CNC machining services in Savannah. We do more than just show off our skills; we aim for perfection. Our engineering services strive to meet the high standards of an industry where being precise is critical.

Our team, deeply knowledgeable about CNC technology, creates custom parts with great care. We don’t just keep up; we aim to lead in advanced manufacturing in Savannah. We push the limits to offer solutions that turn big ideas into reality.

Mekalite is known as a leader in precision CNC machining services because we focus on making sure our customers are happy. Let us turn your engineering challenges into successes. We aim to raise the bar for manufacturing in Savannah and beyond.

Key Takeaways

- Innovative CNC machining Savannah services that set a new standard in manufacturing precision.

- Expertly delivered precision engineering services meeting industry-specific needs.

- Advanced CNC technology solutions that provide a competitive edge.

- Robust quality assurance processes that guarantee satisfaction.

- Custom-tailored advanced manufacturing Savannah services for diverse sectors.

Exploring the World of Precision CNC Machining Services

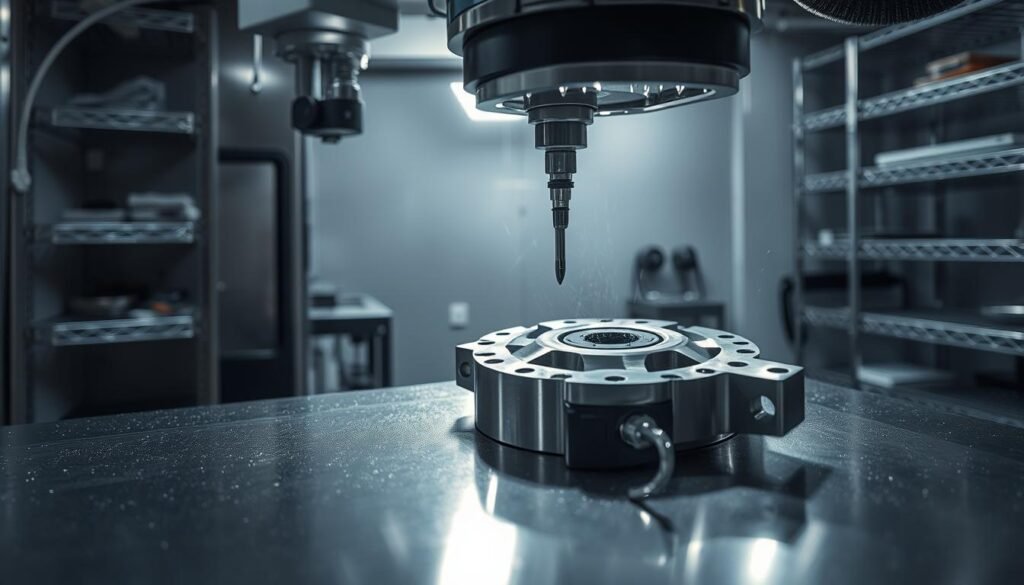

In the heart of today’s manufacturing lies precision CNC machining. It’s key for manufacturing innovation and fast efficient production. By using advanced CNC technology, the future of making things in various sectors shines bright. It shows how vital precision is for unmatched results.

What is Precision CNC Machining?

Precision CNC machining means computers control tools to make precise parts. They follow designs from CAD or CAM software. This controls the tool paths on many axes for intricate shapes. It’s a foundation of CNC’s impact, pushing forward with precision and efficiency.

The Importance of Precision in Manufacturing

In manufacturing, small details make a big difference. Precision CNC machining makes sure each part is perfect. This affects how well things work and their quality. Fields like aerospace, cars, and healthcare depend on this exactness. Precision avoids mistakes in large production batches.

How CNC Technology is Transforming Industries

CNC tech brings modernization and flexibility to making things. It cuts production times and easily accepts design changes. It’s key for innovation across industries. It lets us create complex designs that meet changing needs and rules.

This move to more automated and sophisticated manufacturing underlines industrial growth. It shows the major role of CNC tech in today’s production world.

Precision CNC Machining Services Near Me Savannah

We take great pride in offering Savannah CNC machining services noted for their precision and reliability. We specialize in creating high-precision components to meet the tough needs of today’s industries. Being a reputable CNC manufacturer in Savannah, our workshop is equipped with the latest machines. This allows us to manage both small and large production tasks.

We know how important quick delivery and being close to our customers is. Being located in Savannah lets us serve the local area well, making sure our clients get their parts quickly. This closeness and our dedication to quality make us a trusted reputable CNC manufacturer in Savannah.

| Service Feature | Benefits to Clients |

|---|---|

| Local Savannah Presence | Quick response and delivery, reduced logistics costs |

| Advanced CNC Technology | Precision and versatility in manufacturing a range of components |

| Dedicated Quality Control | Consistency in high-precision components, meeting industry standards |

| Customizable Production Runs | Flexibility in order size, from prototypes to full-scale production |

We are committed to using cutting-edge technology and satisfying our customers. Our Savannah CNC machining service is reliable for companies that value quality. By partnering with us, businesses gain an ally that knows the significance of well-made, precise components.

Materials and Techniques in CNC Machining

We work hard to be the best at CNC machining. This means we always use the materials for CNC machining and cutting-edge machining techniques that the industry demands. By using a variety of materials and the latest tech, we provide industry-specific CNC solutions that fit what our clients need.

Commonly Used Materials in CNC Machining

Choosing the right materials is key to making top-notch machine parts. We use more than 100 metals, like carbon steel and aluminum, and over 200 kinds of high-grade plastics. These materials help us make parts for many sectors, including electronics and aerospace.

Innovative Machining Techniques for Optimal Results

We use a lot of modern machining methods, like 5-axis milling and laser cutting. These techniques are precise and efficient, allowing us to meet tight tolerances and high quality. For a closer look at what we can do, check out our Savannah services page here.

Custom Solutions for Diverse Industry Needs

Different industries need different machining solutions. We offer everything from durable auto parts to tiny medical device components. To make our products even better, we also apply treatments like anodizing and chromate plating.

Our main goal is to make our clients happy by ensuring our products have the best material qualities and dimensions. Our continuous investment in tech and training helps us stay ahead in our field. It makes us crucial partners for our clients’ success.

Industries Benefited by CNC Machining Services in Savannah

Savannah CNC services greatly improve local industries. They help sectors that need very precise and well-made parts.

Aerospace and Defense: A Prime Beneficiary

The aerospace and defense industries demand the best in component quality and reliability. Savannah’s aerospace CNC machining makes sure every part meets tough standards. These standards are for performance and safety.

This machining creates complex parts needed for both commercial and military planes.

Automotive Industry: Driving Forward with Precision

The automotive sector is always looking for better engineering to improve cars. CNC machining makes crucial precision parts. These include engine components and suspension units, leading to enhanced vehicle performance and longer life.

Healthcare and Medical Devices: The Role of CNC Machining

The medical device sector greatly benefits from Savannah CNC services. High precision and reliability are crucial for medical devices. CNC machining makes everything from implants to surgical tools with the needed accuracy and cleanliness. This ensures healthcare workers have the best tools for care.

| Industry | Components | Benefits of CNC Machining |

|---|---|---|

| Aerospace | Engine parts, structural components | Precision, reliability, customization |

| Automotive | Engine components, suspension units | Increased performance, safety |

| Healthcare | Implants, surgical tools | Accuracy, sterility, reliability |

Choosing the Right CNC Machining Service in Savannah

Finding the right CNC service is crucial for businesses in Savannah. It heavily impacts their success. There are many things to think about, from tech skills to how well they help customers. By focusing on local CNC machining, companies get better and more customized services.

To pick a quality CNC provider in Savannah, look deeper than what’s on the surface. Let’s talk about the important features to keep an eye on:

What to Look for in a CNC Machining Service Provider

Choosing a CNC service is all about their quality, flexibility, and speed. The best ones provide great work, meet various design needs, and are punctual. They also help improve your products and make your processes smarter.

The Importance of Localized Services for Businesses

Going local with CNC machining isn’t just about being close. It also means working together easily, fixing problems quickly, and getting personal service. For Savannah’s companies, this choice cuts down on shipping costs, boosts the supply chain, and helps the local economy. This makes choosing a local CNC provider a smart business decision.

| Criteria | Benefits of Local CNC Services | Benefits of Distant CNC Services |

|---|---|---|

| Delivery Speed | Reduced transport times, quicker turnaround | Potentially lower costs but higher risk of delays |

| Communication | Direct, personal interaction, easy site visits | Primarily digital communication, potential timezone issues |

| Support for Local Economy | Direct economic benefits to local community | No significant local economic impact |

| Customization Flexibility | Easier customization due to close partnership | Limited customization due to logistical complexities |

In the end, picking a quality CNC provider Savannah means looking at their tech and service. Knowing the benefits of local CNC machining helps businesses in Savannah make a choice that fits them well.

Testimonials and Success Stories

We’re really proud of the great feedback our CNC machining efforts have received from clients in Savannah. These stories do more than just show off our skills. They show the real difference we’ve made in many areas.

Here are a couple of successful CNC manufacturing stories and reviews from Savannah. They highlight how precise and efficient we are.

| Industry | Feedback | Outcome |

|---|---|---|

| Aerospace | “Precision and reliability are paramount in our industry, and this team delivers exactly that. Exceptional detail in CNC machining and on-time delivery every time.” | Increased production efficiency by 20%, reduced waste by 15% |

| Automotive | “Their innovative approach to CNC machining has significantly cut down our production times and costs.” | Production time cut by 30%, cost savings of 25% per unit |

| Medical Devices | “The precision in machining complex components has been critical for our sensitive devices. Outstanding results and impeccable service.” | Enhanced component precision, leading to a 45% increase in client satisfaction |

Our constant dedication to quality shines through in these reviews from Savannah CNC services. Each story proves our skill and our smart way of tackling client problems. That’s why we keep strong ties with industry leaders.

Conclusion

Mekalite shines as a top CNC machining leader, perfectly placed near Savannah. We aim to be a reliable manufacturing ally. We guarantee precision in every solution, aiming to exceed what our clients hope for. Our deep know-how and advanced tech enable us to meet diverse needs, from small prototypes to big manufacturing projects.

We’re proud of our vital role in boosting businesses’ manufacturing strength in various sectors. At Mekalite, everything we do is about precision and trust. By choosing us, you’re picking a Savannah partner committed to outstanding work. We promise to help your business grow with carefully crafted solutions.

Staying ahead in a changing industry is our priority. We always improve our methods and grow our services to be the best. For those who value quality and precision, Mekalite is the top choice. We’re excited to show you our skills and help make your projects successful.

FAQ

What is Precision CNC Machining?

Precision CNC machining uses computers to guide tools in making parts very accurately. It is crucial for pieces needing exact precision and complicated designs.

Why is precision important in manufacturing?

Precision keeps manufactured parts reliable, high-performing, and consistent. It ensures the whole assembly works, meets set standards, and functions as intended.

How is CNC technology transforming industries?

CNC technology is changing industries by making the production of precise parts faster. It also allows quick changes in design. This boosts product quality, cuts production time, and fosters innovation.

What materials are commonly used in CNC machining?

We use various materials in CNC machining, like aluminum, stainless steel, titanium, plastics, and composites. We choose them based on industry standards and needs.

What innovative machining techniques does Mekalite utilize?

Mekalite uses advanced techniques like 5-axis milling and EDM. These help us make even the most complex parts excellently.

Can you provide custom CNC solutions for specific industry needs?

Yes, we offer customized CNC machining for many industries, such as automotive, aerospace, and healthcare. We tailor our work to fit your design and functionality requirements.

What industries in Savannah benefit most from CNC machining services?

Industries like aerospace and defense, automotive, and healthcare in Savannah really benefit from our services. They need highly precise parts for their manufacturing.

What should I consider when selecting a CNC machining service provider in Savannah?

Look at their expertise, technology, quality commitment, and timeliness. Providers like Mekalite offer good communication, quick service, and chances for direct collaboration, improving your experience.

How does Mekalite ensure the quality of its machined parts?

Mekalite focuses on quality by conducting thorough inspections, using advanced measuring tools, and following strict standards. This makes sure our parts satisfy all requirements and surpass our clients’ expectations.

Can Mekalite handle both prototyping and large-scale production?

Yes, we can do both prototyping and mass production with the same precision and skill. Our technology and team can adjust our services to your needs.