We’re at the cutting edge of making parts, using precision CNC machining to craft custom aluminum pieces. These pieces show how skilled and careful we are. Our CNC services in Houston are all about innovation. We use top-notch tech to meet our clients’ complicated needs. Our team is very skilled. They use modern machines to make products that are very precise and work very well. These products are for industries that need things to be just right.

We make things fast without giving up on quality or reliability. So, we lead in making excellent stuff right here in Houston. When we work with you, it’s more than just a job. We build strong partnerships by making parts that are really well-made. We’re not just any CNC place. We’re leading the way in making things precise in the big world of American industry.

Key Takeaways

- Innovative precision CNC machining tailored for complex needs.

- Custom aluminum components crafted with unmatched skill.

- Comprehensive Houston CNC services for diverse industry demands.

- Rapid delivery of quality-driven CNC solutions.

- Advanced manufacturing converging with impeccable technical expertise.

Understanding CNC Machining and Its Importance

The CNC machining process is key in today’s manufacturing. It offers unmatched precision and efficiency. With a growing demand for high-precision components, it’s vital to know how CNC machining works. This part talks about CNC machining, its benefits, and its special role in producing accurate aluminum parts.

What is CNC Machining?

CNC machining, short for Computer Numerical Control, uses computers and tools to shape a piece of material into a custom part. This method is perfect for making high-precision components. It’s well-known for its precision in working with aluminum, which is important for many industries.

Advantages of Computer Numerical Control

One key benefit of CNC is making complex shapes accurately with less waste. This makes it good for both the economy and the environment. CNC machines are very precise and give the same quality every time. They also cut down on labor costs and make workplaces safer by reducing the risk of accidents.

Precision in CNC Aluminum Parts

The CNC machining shines when making aluminum parts. It can meet tight tolerances and perfect finishes, critical for aerospace, automotive, and healthcare fields. The aluminum machining accuracy shows why CNC machining is a must-have for today’s manufacturing.

The Role of Technology in CNC Machining

We are always pushing to lead in the manufacturing world. Adding top technologies to CNC machining helps us work better and make superior products. We use the newest CNC tech advancements to make parts that precisely fit what our customers need.

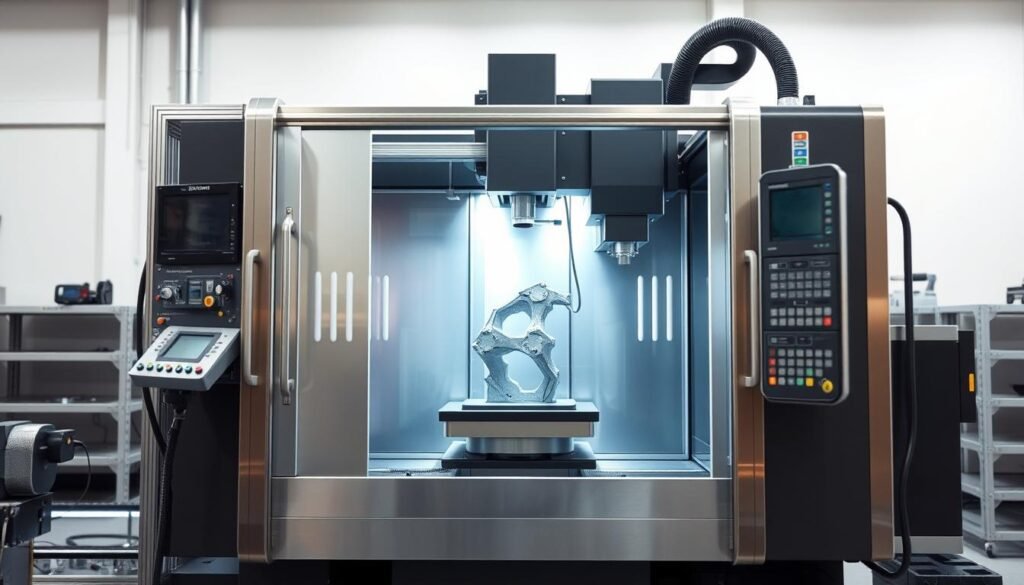

Advanced Equipment Used in CNC

Our places have the latest CNC machines, including vertical and horizontal machining centers. These machines can work with up to four axes. This lets us craft complex shapes with great accuracy.

Achieving High Tolerances

Getting very accurate measurements is key in fields that need exactness. With our top-notch CNC gear and careful checks, we make sure every piece is perfect.

Software and 3D Modeling in Machining Service

CNC software and 3D CAD modeling change how we make things. These tools help us quickly prototype, analyze, and tweak parts before making them. This saves time and money.

We’re all about accuracy and new ideas in our machining work. By using the latest tech and keeping our methods up to date, our service is not only fast but reliable too. With strong CNC machines, advanced software, and deep checks, we ensure our clients are more than happy every time.

Industries Served by CNC Machining Services

In Houston, our CNC machining services support many industries with high precision. We meet the unique needs of each sector with our advanced technology. Here, we focus on how we help aerospace, automotive, and oil & gas industries.

Aerospace Components

We specialize in aerospace CNC machining for making critical aircraft and spacecraft parts. These components need to be highly accurate and durable. They must withstand extreme conditions. Our machining is key in aerospace for everything from the fuselage to engine parts.

Automotive Parts Production

The automotive sector values reliability and efficiency. We make automotive industry components that boost performance and safety. From engine blocks to transmission gears, we aid in creating dependable and innovative automotive designs.

Oil & Gas Industry Applications

Oil and gas work demands tough equipment for tough conditions. Our oil and gas CNC solutions make durable components for exploration and extraction. With our precision CNC machining, every piece aids in safe, efficient operations.

CNC Aluminum Parts Houston

In Houston’s active manufacturing scene, we lead in offering top-notch Houston CNC aluminum machining services. We’re committed to custom aluminum manufacturing. This lets us make precision engineered aluminum parts that satisfy the tough requirements of various fields. Every project gains from our high-tech machining and detailed focus, ensuring top quality and function.

Our facility uses advanced technology for any size production, from small to large runs. This means we can adjust our services for each client, handling complexity and size with great skill. Our team’s skill in working with aluminum results in parts that meet tight standards and boost the durability and performance of their applications.

We’re proud of our clear communication during manufacturing, making sure we fully meet client needs. By focusing on custom aluminum manufacturing in Houston, we don’t just create superior parts. We also form strong, lasting connections with our clients through dependability and clear processes.

For projects requiring highly precision engineered aluminum parts, turn to our Houston CNC aluminum services. Let us show you our precision, skill, and customer-first service that make us stand out.

Choosing the Right Houston Machining Service Provider

When picking CNC services in Houston’s manufacturing scene, it’s key to know what sets top providers apart. It’s more than just choosing a supplier. It’s about finding a partner that stands for Houston machining excellence. A prime example is Custom Components & Assemblies, Inc., known for their high-quality custom components.

Factors to Consider

Before choosing a CNC service in Houston, look at these key points:

- Technical expertise and machinery capabilities

- Ability to adhere to tight tolerances

- Flexibility in handling different materials and complex designs

- Proven track record with case studies or client testimonials

- Cost-effectiveness without compromising on quality

By checking these factors, you ensure your choice not only meets but surpasses your project’s needs, showcasing Houston machining excellence.

Custom Components & Assemblies, Inc.

At Custom Components & Assemblies, Inc., we’re all about top-quality manufacturing. We meld advanced technology, skilled craft, and strict quality checks to serve various industries. This approach guarantees clients get components that match their exact needs.

We are dedicated to selecting CNC services that enhance production while upholding quality. This commitment places us as a top choice for businesses needing reliable, accurate, and advanced CNC machining solutions.

Conclusion

In Houston’s lively manufacturing world, we’re fully dedicated to leading in Houston CNC machining. We aim higher than the standard, offering manufacturing solutions that focus on our customers’ unique needs. Using the latest technology and our deep understanding of the industry, we ensure every project is done perfectly.

We are committed to pushing forward with innovative CNC solutions. Our skill in creating precise parts, with tolerances as tight as ±0.0004″, and our experience with over 40 materials make us leaders in precision engineering. Our wide range of services, including CNC machining, plastic injection molding, and rapid prototyping, shows how far our impact goes.

For companies that value top-notch quality and dependability, choosing the right partner is crucial. Our goal is to exceed such expectations through our comprehensive quality assurance, cutting-edge inspection facilities, and broad service offerings. If you’re interested in learning more, or want to see how we can improve your manufacturing process, we invite you to look at our innovations and get in touch for a growth-focused manufacturing partnership.

FAQ

What is CNC Machining?

CNC machining uses computer tech to steer machine tools. This process creates parts accurately. It cuts down on errors and ensures parts meet exact specs with little need for people to step in.

What are the advantages of Computer Numerical Control?

CNC’s benefits include quick production, steady quality, and making complex shapes. It speeds up making things, cuts down waste, and lowers mistakes. This means products are made precisely.

How precise are CNC aluminum parts?

CNC aluminum parts are very exact, hitting tolerances as close as +/- .0002 inches. Such accuracy is critical for industries like aerospace, automotive, and oil & gas that need very precise components.

What advanced equipment is used in CNC machining?

We use top-notch gear like CNC vertical machining centers, with up to four-axis. And, CNC horizontal machining centers. This equipment helps us reach high accuracies and complex designs consistently.

How does software and 3D modeling enhance machining service?

Software and 3D modeling help us design accurately, reverse engineer, and tweak designs before making them. This helps us meet customer needs with high precision.

What industries benefit from your CNC machining services?

We serve many sectors including aerospace, which needs light yet strong parts; automotive, which requires reliable and tough parts; and the oil & gas industry, which wants robust components.

How do you ensure the quality of CNC aluminum parts?

We follow strict quality control at every manufacturing step. We inspect every part to make sure it meets top standards for accuracy and performance.

What factors should businesses consider when choosing a CNC machining service provider in Houston?

Companies should check a provider’s tech skill, types of materials they can work with, and their service range. They should also look at how fast they work, if they’re cost-effective, and their quality history.

Why should businesses choose Custom Components & Assemblies, Inc. for their CNC machining needs?

Pick us for our full range from prototyping to big production. We mix skilled people, advanced tech, and a focus on precise work to meet the manufacturing sector’s needs.