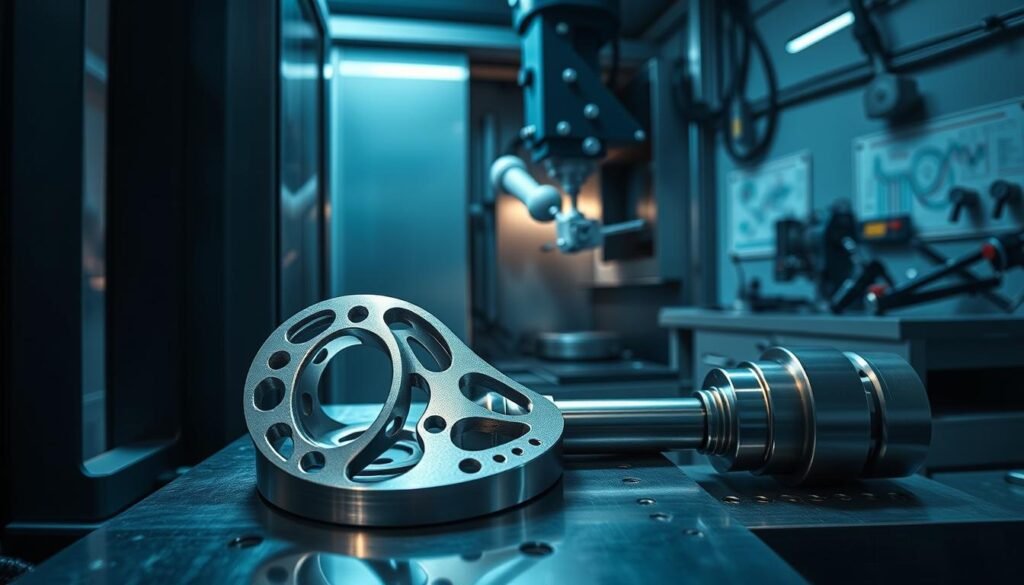

In San Diego’s busy healthcare scene, CNC medical device making stands out. It’s known for spot-on precision and high-tech skills. Companies here are all about fine details, pushing technology in medicine further. They make devices that are top-notch in both quality and how they work.

We excel with top-of-the-line CNC machines, like 3-axis and 5-axis CNC machines. These machines help make very detailed parts with super tight fits needed for medical devices. It’s our mix of cutting-edge tech and expert people that lets us make small batches of essential medical tools without losing quality or function.

Key Takeaways

- San Diego’s distinguished CNC medical device production landscape.

- The central role of precision machining in quality healthcare solutions.

- How advanced technology ensures reliability and accuracy in medical manufacturing.

- The benefit of low-volume production in meeting diverse medical needs.

- Our commitment to the highest standards of production in the healthcare sector.

Introduction to CNC Machining for Medical Devices

CNC machining is a process where computers control machinery with high precision. It follows exact commands. This accuracy is key in the medical device industry. Here, precision means everything for reliability and safety.

What is CNC Machining?

CNC machining definitions mean computers automate tool control. A software directs all movements. This ensures the consistent and precise production of complex parts. Vital in making medical devices, it adheres to tiny, exact measurements.

The Importance of Precision in Medical Device Manufacturing

Precision in medical manufacturing is critical. Small errors can have big effects, affecting patient health. CNC machining guarantees each part meets strict standards. This is crucial for their function, durability, and safety.

Why San Diego Is a Hub for CNC Medical Device Manufacturing

San Diego manufacturing excels in high-precision medical devices. It’s known for cutting-edge technology and skilled workers. With top CNC technologies, it leads in medical device innovation and quality.

The Role of Darmark Corporation in the Industry

Darmark Corporation plays a big role in the machining industry. We have years of experience and focus on quality. Our work in machining excellence uses the latest tech and standards. We support important fields like aerospace, defense, and medical devices in San Diego.

Our skilled machinists combine deep knowledge with new ideas. This expertise lets us handle complex work with top-notch results. We always exceed what our customers expect.

Decades of Machining Experience

Our work is known for being efficient and precise. Darmark Corporation’s deep knowledge shows we can keep up with new tech changes. Our clients count on our machining excellence throughout their projects.

We promise high-quality and we prove it. We’re proud to have ISO9001:2015 and AS9100D certifications. These aren’t just awards; they reflect our careful, standard-compliant work on every project. This way, we support a variety of industries as a trusted partner.

Contributions to Local and Diverse Industries

Darmark Corporation helps more than just industries. We help the local economy grow by supporting different businesses. We’re part of San Diego’s economy, helping from small startups to big companies with our advanced manufacturing and support.

CNC Medical Devices San Diego

In San Diego, the creation of CNC medical devices is outstanding. It’s known for precision and high quality. Local producers make crucial medical-grade parts. These are key for the medical, pharmaceutical, and aerospace fields. This effort makes San Diego medical device manufacturing well-known. It also boosts the city’s role in health tech innovation.

Businesses use top CNC tech to make exact parts needed in medicine. They focus on making every piece, like surgical tools and diagnostic gear, work perfectly. This improves patient care. They also follow strict standards like ISO9001:2015 and AS9100D, showing their commitment to quality in manufacturing.

| Component | Material Used | Application |

|---|---|---|

| Orthopedic Implants | Titanium | Joint Reconstruction |

| Surgical Instruments | Stainless Steel | Operative Procedures |

| Dental Tools | Carbide | Dental Surgery |

San Diego medical device manufacturing combines with advanced CNC precision. This way, local companies are achieving and setting global standards. They’re ready to meet all kinds of needs with flexible answers. This is crucial for making new medical tech. It ensures top quality and safety are always a priority.

Advanced CNC Machining Technologies and Services

In the medical device making world, CNC tech growth is key in pushing healthcare forward. Swiss machining is at the heart of this, blending top manufacturing techs. Together with CNC milling, turning, and precision grinding, it makes sure medical devices are top-quality, which is critical for patient care.

CNC Milling and Turning Services

We’re leaders in CNC milling and turning. We work with 4-axis and 5-axis machines that help make complex parts precisely. These methods are vital for the sophisticated functions of medical devices.

Precision Grinding Services for Medical Devices

Precision grinding is a big part of what we do. It gets surfaces super smooth and fits parts within tight tolerances. This step is crucial for medical devices to work right and be reliable, where even a tiny error can affect outcomes.

Swiss Machining: The Next Level of Precision

Swiss machining is all about extreme accuracy. It uses high-tech methods like EDM and detailed drilling to make incredibly precise parts. These are needed for special medical uses.

| Technology | Feature | Benefit to Medical Device Manufacturing |

|---|---|---|

| CNC Milling and Turning | 4-axis and 5-axis capabilities | Makes complex shapes possible and boosts how fast we can make things |

| Precision Grinding | Sub-micron accuracy | Ensures surfaces are just right for device to work well |

| Swiss Machining | EDM and precise drilling | Helps make very precise, high-quality parts |

By combining CNC milling, turning, precision grinding, and Swiss machining, we boost our manufacturing strength. This mix helps us create better, more reliable medical devices. It shows how we keep up and go beyond what the healthcare field needs.

American Precision Tool’s Comprehensive Machining Solutions

At American Precision Tool, we are proud to offer comprehensive machining solutions. We meet the needs of industries looking for precision and efficiency. Our skills range from early CNC prototyping to high-volume machining. This ensures each project gets top-notch expertise and quality.

We are a key part of the San Diego business support network. We help the local economy by boosting the tech skills of area companies. Our wide range of services helps businesses grow and innovate. We will now share how our machining services work. It shows our dedication to excellence from start to finish.

| Service | Description | Benefits |

|---|---|---|

| Prototyping | Quick turnaround CNC prototyping to refine product designs | Enhances design accuracy, reduces overall project cost |

| High-Volume Machining | Efficient production of large quantities utilizing advanced machining centers | Cost-effective for mass production, ensuring consistent quality |

| Quality Assurance | Rigorous testing and compliance with ISO9001:2015 / AS9100D standards | Maintains high standards, mitigates risk, and ensures customer satisfaction |

To support San Diego business support, we offer comprehensive machining solutions. We always try to improve our methods. This leads to top-quality products for both small and large orders.

Our commitment and expertise have made us leaders in manufacturing. We always aim to go beyond what’s expected in every project.

Why Quality Matters in CNC Machined Medical Devices

When making medical devices, quality and precision are very important. That’s because they directly impact patient safety and how well the device works. In a place like San Diego, known for medical breakthroughs, the focus on high-quality CNC machining is crucial.

The Impact of Precision on Patient Safety and Device Efficacy

The accuracy of CNC machined parts is key to the medical devices’ function and trustworthiness. Even tiny errors can cause device failures or mistakes, risking patient health. So, we control our machining processes tightly. This makes sure every part meets tough standards, which protects patient safety and boosts device efficacy.

Maintaining Regulatory Compliance Through Quality Machining

Following regulatory standards strictly is a must in medical device production. It helps with getting market approval and assures users the product is safe and effective. Our focus on regulatory compliance is shown by sticking strictly to rules and standards like ISO9001:2015 and AS9100D. These certifications prove our commitment to making reliable, top-quality medical devices.

By combining state-of-the-art technology with detailed workmanship, we make sure every CNC machined part ensures patient safety, keeps device efficacy, and follows regulatory compliance. These are the signs of high-quality CNC machining.

Conclusion

In our journey through CNC medical device manufacturing, we’ve highlighted San Diego’s key role. This city helps set the high standards in precision device making. Companies like Darmark Corporation and American Precision Tool are at the forefront, making San Diego a leader in this area. Their work helps earn the city a reputation for excellence and skill.

San Diego’s focus on quality in CNC medical device manufacturing keeps its legacy of innovation alive. It leads to safer, better healthcare everywhere. Our local precision engineering firms are part of creating a future with advanced medical care. They are known for superb craftsmanship and strict standards, raising the bar worldwide.

Our mission is to offer unmatched precision and performance in machining. As part of San Diego’s manufacturing sector, we aim to address the healthcare industry’s needs. Our innovate spirit and deep experience make us reliable experts in medical device manufacturing.

FAQ

What is CNC Machining?

CNC machining is a way to make things by controlling machines with computers. It’s used to make parts with great accuracy. This method is key for making complicated pieces for medical devices accurately.

Why is Precision Important in Medical Device Manufacturing?

In making medical devices, being exact is crucial. It makes sure the devices are safe and work right. Since these devices are used in the body, they must be made perfectly.

What Makes San Diego a Hub for CNC Medical Device Manufacturing?

San Diego is a top place for making CNC medical devices. It’s because of its location, skilled workers, and advanced technology. The area’s makers are known for their long experience and high standards.

What Experience Does Darmark Corporation Bring to the Industry?

Darmark Corporation has 40 years of experience. They are known for their skills, high-tech making, and sticking to quality rules. They hold ISO9001:2015 and AS9100D certifications, showing they meet high standards.

What Certifications Emphasize Commitment to Quality?

ISO9001:2015 and AS9100D are key quality certifications. They show a company meets strict rules and high safety and quality standards. These are especially important in making medical devices.

How Does Darmark Corporation Contribute to Local and Diverse Industries?

Darmark Corporation helps the local economy and many industries by providing precise CNC machining services. They help industries like biomedical, pharmaceutical, and aerospace grow in San Diego.

What Advanced CNC Machining Technologies Are Used in Medical Device Manufacturing?

In making medical devices, advanced CNC tech like milling, turning, and Swiss machining are used. These methods allow for very detailed work, meeting the medical field’s strict requirements.

How Does American Precision Tool Ensure Quality Across Production Stages?

American Precision Tool keeps high quality by using strict checks and keeping up with ISO 9001:2015 / AS9100D certification. They check everything carefully and always look for ways to do better, meeting or beating customer and rule requirements.

What is the Significance of Regulatory Compliance in Machined Medical Devices?

Following rules is very important for machined medical devices. It means they meet the safety and performance standards they need to. Precision machining sticks to these tough rules and quality systems.

Why Do San Diego Manufacturers Maintain Industry Standard Certifications?

San Diego manufacturers keep certifications like AS9100D to show they are dedicated to top-quality management. These global certifications show they follow the best practices and rules needed for crucial work like medical device making.