Physical Vapor Deposition (PVD) coating is a cutting-edge surface treatment technology that applies thin, high-performance films to enhance the durability, functionality, and aesthetics of materials. As industries like aerospace, electronics, medical devices, and green energy demand more robust and sustainable solutions, PVD is evolving rapidly. In 2025, the PVD market is poised for significant growth, driven by technological advancements, environmental considerations, and smart manufacturing integration. This article explores the fundamentals of PVD, its latest developments, innovative applications, and future directions, offering a fresh perspective on its transformative potential.

What is PVD Coating?

PVD is a vacuum-based process where a solid material, such as metal or ceramic, is vaporized and deposited as a thin film onto a substrate. This creates coatings typically ranging from 0.5 to 5 micrometers thick, improving surface properties like hardness, wear resistance, corrosion resistance, and visual appeal. Unlike chemical-based methods like electroplating, PVD is a physical process, making it cleaner and more environmentally friendly.

How PVD Works

The PVD process involves three key steps:

- Vaporization: The coating material (target) is converted into a vapor using techniques like sputtering or evaporation.

- Transportation: Vaporized particles travel through a vacuum chamber to the substrate.

- Deposition: The vapor condenses on the substrate, forming a uniform, adherent thin film.

This process occurs at relatively low temperatures (50–600°C), making it suitable for heat-sensitive materials. The result is a high-purity coating with excellent adhesion and customizable properties.

PVD Coating Techniques

Several PVD techniques are used, each tailored to specific applications:

| Technique | Description | Applications |

|---|---|---|

| Sputter Deposition | Uses plasma to eject atoms from a target, depositing them on the substrate. Offers precision and versatility. | Semiconductors, optics, solar cells |

| Arc Vapor Deposition | Generates a high-ionization plasma via an electric arc, creating dense, uniform coatings. | Wear-resistant coatings for tools |

| Evaporation | Heats the target material to vaporize it, then deposits it on the substrate. | Decorative coatings, electronics |

| Ion Plating | Combines evaporation with ion bombardment for enhanced adhesion and density. | Aerospace components |

| Electron Beam PVD (EBPVD) | Uses an electron beam to vaporize the target, ideal for high-performance coatings. | Turbine blades, thermal barriers |

Recent innovations, such as barrel PVD coating machines, enable uniform coating of complex components like ball bearings and fasteners by tumbling them in a rotating drum, expanding the technology’s reach.

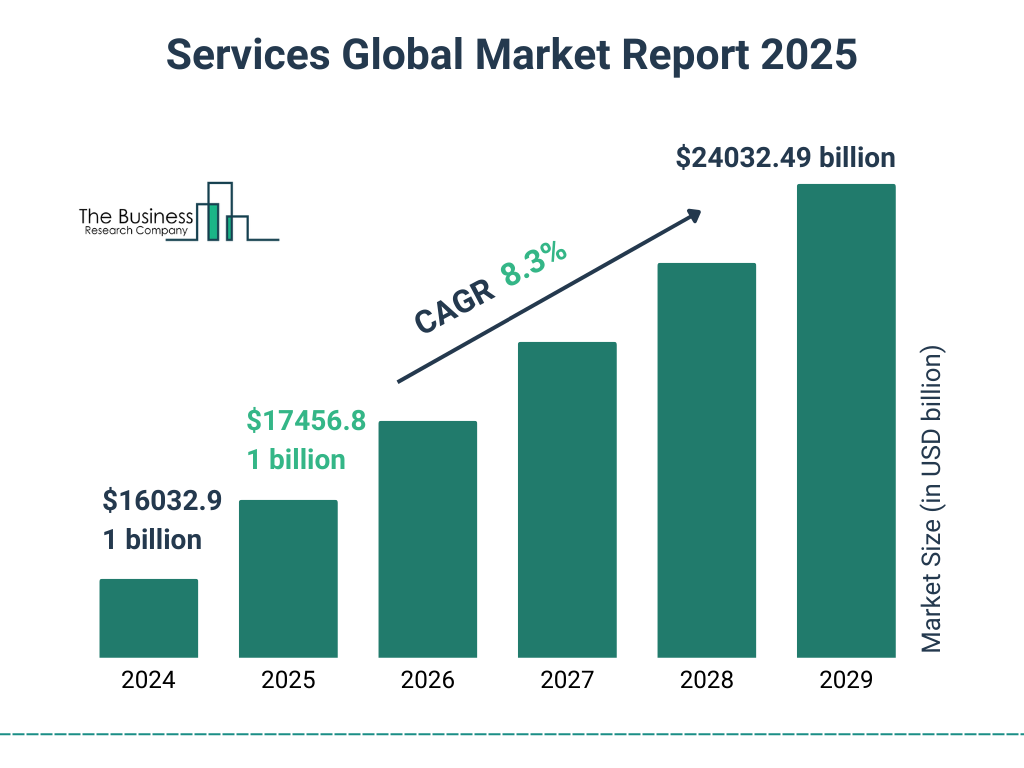

Market Growth and Global Trends

The global PVD market is on a steep growth trajectory, projected to rise from USD 29.41 billion in 2024 to USD 57.04 billion by 2032, with a CAGR of 8.6% (Fortune Business Insights). This growth is driven by:

- Electronics Boom: Increasing demand for complex semiconductors and microelectronics.

- Green Energy: PVD’s role in coating solar cells and energy storage devices.

- Medical Advancements: Biocompatible coatings for implants and surgical tools.

- Aerospace and Automotive: Need for wear-resistant, high-performance components.

Europe leads in sustainable PVD adoption, with policies promoting low-toxic, energy-efficient processes. The EU Chips Act is set to boost PVD use in semiconductor manufacturing, strengthening Europe’s position in the global market (Vaccoat). Meanwhile, Asia-Pacific and North America are seeing rapid growth in automotive and aerospace applications.

Emerging Trends in PVD Technology

PVD is evolving to meet modern challenges, with several exciting trends shaping its future:

Nanoscale Coatings for Precision

The push for miniaturization in electronics and medical devices has led to advancements in nanoscale PVD coatings. These ultra-thin films, controlled at the atomic level, are critical for nanoelectronics, sensors, and medical implants. For example, PVD enables precise coatings for next-generation microchips, supporting the EU Chips Act’s goals (Stanford Advanced Materials).

Sustainable PVD Processes

Environmental concerns are driving the development of eco-friendly PVD methods. Researchers are exploring non-toxic coating materials, such as zirconium nitride (ZrN), and optimizing energy-efficient deposition techniques. These efforts align with global sustainability goals, reducing the environmental footprint of manufacturing.

Industry 4.0 Integration

PVD is embracing smart manufacturing through Industry 4.0. By integrating artificial intelligence (AI) and the Internet of Things (IoT), PVD systems can offer real-time monitoring, predictive maintenance, and adaptive control. This enhances efficiency, reduces downtime, and ensures consistent coating quality, making PVD more competitive in high-volume production.

Innovative Applications and Materials

PVD’s versatility is expanding through new materials and applications:

- High-Entropy Alloys (HEAs): These advanced coatings combine multiple elements to achieve superior hardness, corrosion resistance, and thermal stability, ideal for aerospace and tooling (TBK Metal).

- Multi-Layer Coatings: Layered structures enhance durability and functionality, offering tailored properties for specific applications.

- Reactive PVD: Allows for customized surface properties, such as specific chemical resistance or color, expanding PVD’s decorative and functional uses.

- Improved Sputtering Targets: Enhanced target materials and vacuum technology reduce energy use and coating time, improving cost-effectiveness.

These innovations are making PVD coatings more durable, visually appealing, and adaptable to diverse industry needs.

PVD in Key Industries

PVD’s impact spans multiple sectors, each leveraging its unique benefits:

| Industry | PVD Application | Benefits |

|---|---|---|

| Aerospace | Wear-resistant coatings for turbine blades and engine parts | Enhanced durability, performance under extreme conditions |

| Medical | Biocompatible coatings for implants, surgical tools | Reduced infection risk, improved longevity |

| Electronics | Thin films for semiconductors, microelectronics | Higher performance, corrosion resistance |

| Automotive | Decorative and functional coatings for engine components, trim | Improved aesthetics, reduced friction |

| Tooling | Hard coatings for cutting tools, molds | Extended tool life, better precision |

For instance, in the medical field, PVD coatings like titanium nitride (TiN) meet ISO 10993-1 biocompatibility standards, ensuring safety for implants (Fortune Business Insights).

Leading Companies in PVD Technology

The PVD market is driven by innovative companies investing in research and development:

- Applied Materials: A leader in semiconductor PVD equipment.

- OC Oerlikon: Known “

for its Surface Solutions segment, offering advanced PVD coatings.

- Lam Research: Specializes in PVD for semiconductor manufacturing.

- ULVAC Technologies: Provides PVD solutions for electronics and optics.

- Buhler Leybold Optics: Focuses on precision coatings for optical applications.

- Von Ardenne, Evatec, Kobe Steel, Veeco Instruments, IHI Hauzer Techno Coating: Contribute to diverse PVD applications, from aerospace to decorative coatings.

These companies are pushing the boundaries of PVD through innovative materials, processes, and equipment, ensuring the technology remains at the forefront of industrial advancements (Vaccoat).

Challenges and Opportunities

Despite its advancements, PVD faces challenges:

- Complex Geometries: Achieving uniform coatings on intricate shapes remains difficult, requiring advanced equipment like barrel coaters.

- Cost: High initial investment in PVD systems can be a barrier for smaller manufacturers.

- Scalability: Adapting PVD for high-volume production while maintaining quality is an ongoing challenge.

However, these challenges present opportunities. For example, AI-driven process optimization can improve coating uniformity, while sustainable materials reduce costs and environmental impact. Continued R&D is expected to address these hurdles, making PVD more accessible and efficient.

Future Directions for PVD Coating

Looking ahead, PVD is set to transform manufacturing in several ways:

- Smart Manufacturing: Full integration with Industry 4.0 will enable autonomous PVD systems, reducing human intervention and boosting productivity.

- Sustainable Innovation: New eco-friendly materials and processes will align PVD with global net-zero goals, particularly in Europe’s green manufacturing initiatives.

- Nanotechnology Expansion: PVD’s role in nanoscale coatings will grow, supporting advancements in quantum computing, wearable electronics, and personalized medicine.

- Cross-Industry Applications: Emerging uses in renewable energy (e.g., solar panel coatings) and biotechnology (e.g., antimicrobial coatings) will broaden PVD’s impact.

These directions highlight PVD’s potential to address modern challenges, from sustainability to technological complexity, positioning it as a cornerstone of future manufacturing.

Conclusion

PVD coating technology is undergoing a renaissance in 2025, driven by market growth, technological advancements, and a focus on sustainability. From nanoscale precision to smart manufacturing integration, PVD is redefining how industries enhance material performance and aesthetics. As companies like Applied Materials and OC Oerlikon lead innovation, and as trends like high-entropy alloys and eco-friendly processes gain traction, PVD’s future is bright. For businesses and professionals, staying informed about these developments will be key to leveraging PVD’s full potential in a rapidly evolving industrial landscape.