In San Diego, the aerospace sector’s growth shines bright. This is thanks to top-grade CNC machined parts. We use a mix of new technology and over 40 years of making experience. This pushes the aerospace field forward. Our team’s skill and our high-tech machines create parts that are the foundation of flight innovation.

We stick to strict standards like AS9100D and ISO9001:2015. This confirms our focus on quality, safety, and reliability. Precision is crucial for making parts fit and for making aviation dreams come true. We meet the unique demands of defense, biomedical, and pharmaceutical areas in aerospace. Our manufacturing is made to reach high standards and beat expectations. In San Diego, our precision drives the aerospace tech boom.

Key Takeaways

- Expertise in CNC machining sets the stage for producing high-quality aerospace components in San Diego.

- Our manufacturing solutions incorporate advanced technology to deliver precision parts with unmatched accuracy.

- By adhering to AS9100D and ISO9001:2015 certifications, we ensure each product meets the highest industry standards.

- Cross-industry experience fortifies our ability to cater to specific needs within the aerospace sphere.

- Dedication to precision machining and technology culminates in exceptional manufacturing outcomes for the aerospace industry.

Introduction to CNC Aerospace Parts Manufacturing in San Diego

San Diego is a key player in the aerospace arena, thanks to leading-edge CNC aerospace components. We are proud to be leaders in advanced manufacturing. Our efforts focus on machining services that meet both local and international needs.

We stick strictly to the tough demands of San Diego precision engineering. This approach makes sure each part meets high standards. These standards are vital for aerospace and defense uses. Learn more about our specialized machining and how we lead in this competitive area.

Our strength is in providing custom solutions with specialized machining services. We tackle all sorts of production challenges, from one-off prototypes to mass production. Our work stands out for its precision, efficiency, and trustworthiness.

| Service | Technology Used | Relevance to Aerospace |

|---|---|---|

| Wire EDM | Sub-micron level precision cutting | Essential for intricate component geometries |

| Sinker EDM | Advanced electrical discharge machining | Perfect for complex shapes and materials |

| Laser Ablation | High precision surface structuring | Ideal for lightweight and high-strength materials |

By using advanced manufacturing techniques, we make sure our CNC aerospace components surpass modern aerospace engineering standards. Our commitment to top-quality work makes us stand out in San Diego precision engineering.

Key Benefits of Precision Machining for Aerospace Components

In aerospace manufacturing, both performance and safety of aircraft parts greatly depend on the precision of machining. Our facility focuses on high-tolerance machining. This is vital for creating parts that not only meet but also surpass aerospace standards.

Advanced machining technologies bring a key benefit: material efficiency. Our CNC tools optimize cutting to reduce waste. This makes production both cost-effective and eco-friendly.

Enhanced Precision and Accuracy

Parts like turbine blades and structural components need the highest precision. Our tailored aerospace solutions ensure precise engineering. This meets design needs for the best aerodynamics and functionality.

Improved Material Utilization

We improve material efficiency through smart machining. This lowers material costs and helps the environment. It supports the aerospace industry’s sustainability goals.

Customization and Flexibility in Production

The aerospace industry is always changing, requiring adaptable production methods. Our CNC machining can handle various materials and shapes. This allows us to take on unique aerospace projects easily.

To learn more about high-precision tools in aerospace, look into innovative aerospace tooling. Such advancements boost the quality and dependability of aerospace parts, meeting the industry’s high safety and performance standards.

CNC Aerospace Parts San Diego

Our facilities are at the cutting edge of aerospace innovation. We use advanced CNC technology to make high-precision parts essential for the aerospace field. Every item we create in San Diego meets the AS9100D quality standards. This shows our dedication to reliability and top-notch aerospace machining.

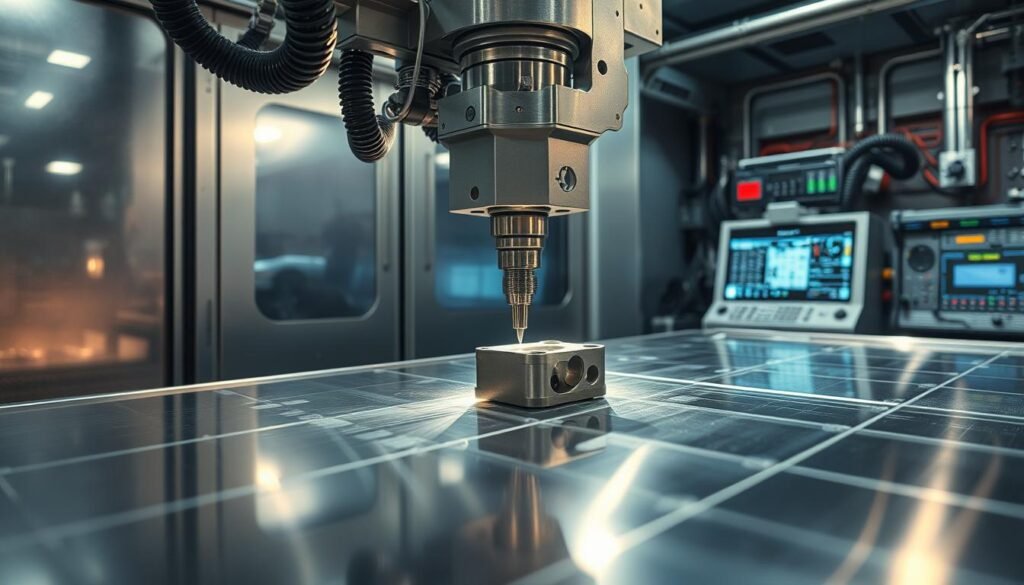

State-of-the-Art CNC Machining Equipment

We’ve invested in the newest CNC machinery to fulfill the complex needs of making aerospace parts. Our gear includes 4-axis and 5-axis machining, along with Swiss machining. This allows us to make precision parts with complex shapes and precise tolerances.

AS9100D Certification and its Importance

Keeping AS9100D certification means more than just following rules. It’s about sticking to the top quality control and management that the aerospace field expects. This certification proves our products and processes are reliable and always high quality. It also helps our clients trust us more.

Local Machining Services Supporting the Aerospace Industry

We’re a key part of local aerospace machining in San Diego. We help the local economy and add to the aerospace industry’s supply chain. Being close by means we can deliver parts quickly and effectively in Southern California. This helps aerospace companies in the area be more agile and responsive.

Advanced Machining Techniques and Technologies Used in Aerospace Parts Production

In the world of advanced precision grinding and aerospace manufacturing technology, we lead the way. We use innovative machining strategies to make aerospace parts very accurately. Our skills meet the aerospace industry’s changing needs, making parts better and more useful.

Advanced precision grinding is key to our work. It lets us give great attention to small details. This way, we can achieve smooth surfaces and exact sizes that aerospace parts must have. Adding the latest aerospace manufacturing technologies makes us more efficient. It also helps us keep up with new aerospace standards.

| Machining Technique | Application in Aerospace | Benefit |

|---|---|---|

| CNC Turning and Milling | Creation of cylindrical and complex 3D shapes | High precision and consistency |

| EDM (Electrical Discharge Machining) | Machining of intricate components from hard metals | Superior accuracy with fine surface quality |

| Laser Cutting and Engraving | Precision engraving and part marking | Enhanced traceability and aesthetics |

| Advanced Precision Grinding | Surface finishing operations | Exceptional surface texture and fine tolerances |

Our commitment to aerospace technology makes our machining better all the time. We make sure every part works perfectly in critical situations. This focus on innovative machining shows our deep expertise and leadership in aerospace.

Examples of Aerospace Components Machined with Precision

In our top-notch facility, we are experts at making aerospace parts with unmatched accuracy. We make crucial parts like aerostructures for planes, engine pieces, models for new designs, and parts that hold planes together. Our work highlights our dedication to being the best in the aerospace field.

We handle everything from big plane structures to small engine parts. Our machining services cover lots of different aerospace needs. We make sure each piece passes tough quality checks. This is super important for safety in flying and space travel.

Aerostructure Components

Aerostructures are key to how well an airplane flies and stays together. We’re really good at making the body parts of planes, the wings, and parts that hold the plane’s frame. Every piece is made to fit perfectly and work great even in tough flying conditions.

Engine Parts

Making engine parts is an art that requires serious skill. Our team makes important parts like turbine blades and pistons. These parts help airplane engines run smoothly and powerfully.

Custom Prototypes and Specialized Fittings

We don’t just make standard parts. We’re also leaders in making models for innovative plane projects. We make custom parts and pieces for specific needs. Our unique skills help us bring new and exciting tech to the world of flying.

Conclusion

We’re wrapping up our talk, and it’s clear we lead in San Diego’s CNC aerospace field. Our dedication to exact engineering and trusted manufacturing sets us apart. With top-notch facilities, following AS9100D standards, and our skilled team, we ensure our aerospace components are of the highest quality. We’re at the cutting edge, using precision machining to meet aerospace’s strict needs.

Our work shows our strong commitment to top service and excellent products. We pay close attention to detail and innovate to make aerospace parts that often exceed what’s expected. In an industry where mistakes can’t happen, we excel. By building strong partnerships and offering tailored solutions, we deliver advanced technology our clients rely on.

We invite you to see what makes us different as a leader in precision engineering. We serve both local businesses and the global market with the same dedication. Our goal remains: to provide precise manufacturing solutions that move the aerospace industry forward. Work with us, and let’s achieve unmatched manufacturing success together.

FAQ

What specific types of CNC machining services does your San Diego facility offer?

We offer diverse CNC machining services. This includes CNC milling and turning, along with 4-axis and 5-axis machining. We also provide precision grinding, Swiss machining, and the use of technologies like EDM (Electrical Discharge Machining).

How does your AS9100D certification benefit customers in the aerospace and defense industries?

Our AS9100D certification means we meet top quality standards for aerospace and defense. It gives clients confidence that our parts fit their crucial needs perfectly.

Can American Precision Tool handle custom aerospace component requests?

Absolutely. We’re all about custom solutions and flexibility. Our setup lets us make unique components that meet your exact needs and designs.

What measures do you take to ensure enhanced precision and accuracy in aerospace part production?

We use the latest equipment and advanced machining for top precision. This careful method ensures we make parts that perfectly match aerospace specs.

How does your machining process contribute to material efficiency and sustainability?

Our processes aim at material efficiency, cutting waste and boosting sustainability. We plan and execute our machining to use materials to the fullest.

How do you support the growth of the aerospace industry in San Diego?

We’re boosting San Diego’s aerospace growth by offering top machining services. This strengthens local manufacturing and the aerospace industry’s expansion.

What kind of aerospace components have you produced?

We’ve made various aerospace components, from aircraft structures to detailed engine parts. Each item is crafted to meet the industry’s high-quality standards.

Do you offer prototype development services for new aerospace designs?

Yes, we develop custom prototypes. This lets clients tweak designs before mass production, aiding in aerospace innovation and development.