At Panek Precision, we lead automotive part manufacturing, specializing in precision CNC components. Our work is a hallmark of Chicago custom machining services. We are committed to excellent quality, making us top providers for automotive needs. Located near Chicago, IL, our advanced 106,000 square foot facility in Northbrook is tailored for crafting exact CNC machined parts.

We aim to not just meet, but redefine standards with our inventive approaches to machining and metal tube cutting. We cater to the automotive sector’s complex needs, backed by ITAR Registration. This shows our focus on top-notch precision, including for military and defense projects. We ensure our high-volume production meets diverse material demands like stainless steel, aluminum, and carbon & alloy steel.

Key Takeaways

- Emphasize the strategic location and state-of-the-art facilities of Panek Precision near Chicago, IL.

- Highlight the expertise in high-precision CNC machining tailored for the automotive industry.

- Mention the range of services like multi-spindle screw machining, metal tube cutting, and 4-slide metal stamping.

- Detail the commitment to quality and precision with ITAR Registration for military and defense projects.

- Spotlight the ability to work with diverse materials, such as stainless steel, aluminum, and carbon & alloy steel, for custom solutions.

The Importance of CNC Machining in the Automotive Industry

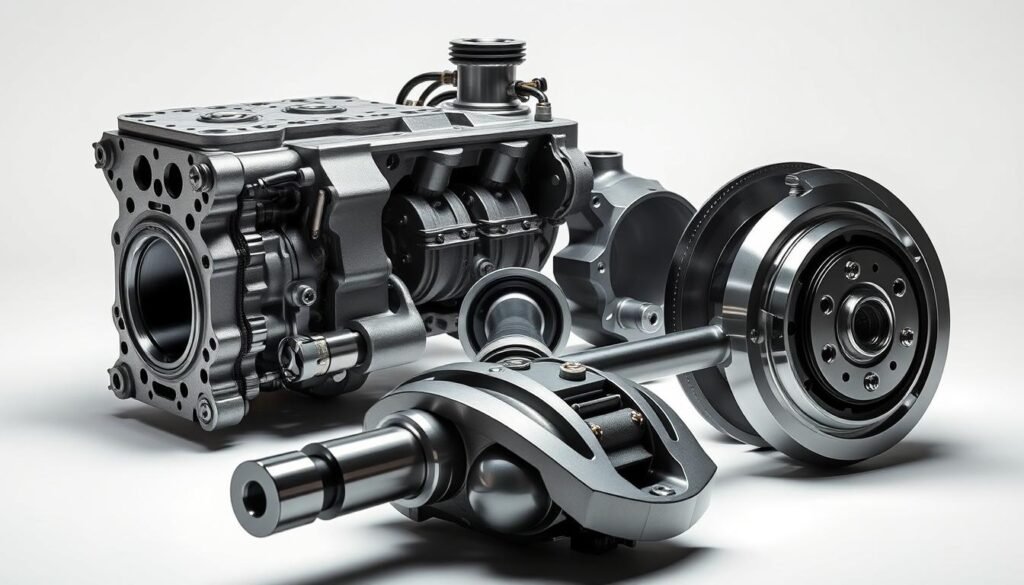

Exploring the critical role of CNC machining in automotive manufacturing reveals its massive importance. Automotive CNC technology is key in making efficient vehicles. It’s all about producing precision engine parts that are both necessary and highly reliable.

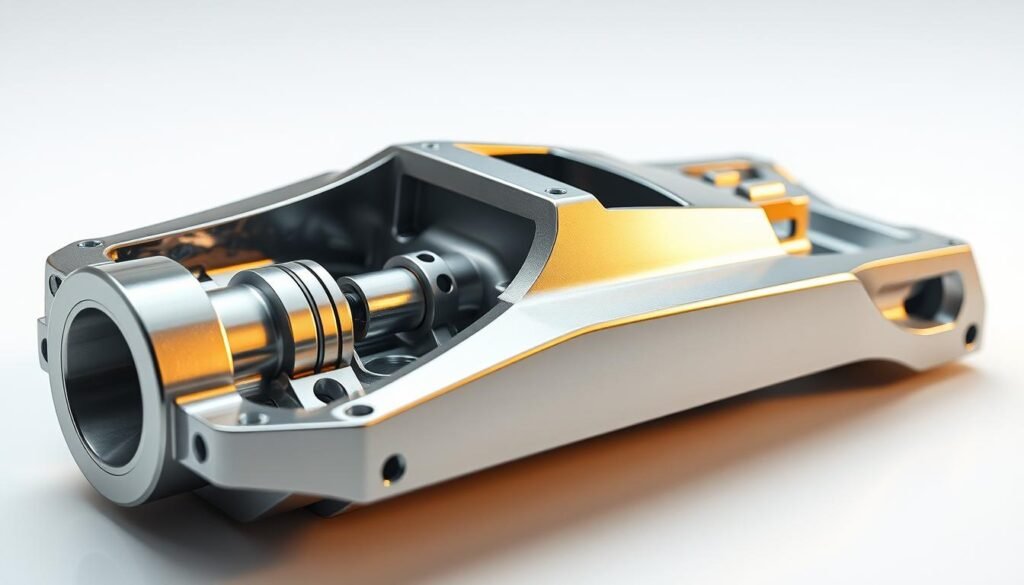

We shine in high-precision automotive manufacturing because of our use of 3, 4, and 5-axis CNC machines. These machines make parts with complex shapes and very close tolerances. They’re crucial for the latest car designs. Speed and efficiency in making cars match well with our CNC machining skills.

The Role of Precision CNC Machining in Automotive Components

The accuracy and quality from precision CNC machining matter a lot for car parts. This CNC tech is perfect for making both few or many parts. Our process can make highly innovative and precise components.

| Component | Technology Used | Tolerance | Importance in Automotive |

|---|---|---|---|

| Engine Parts | 5-axis CNC Machining | ±0.005 in | Crucial for engine efficiency and longevity |

| Suspension Components | 4-axis CNC Machining | ±0.010 in | Essential for vehicle stability and safety |

| Transmission Components | 3-axis CNC Machining | ±0.005 in | Key to smooth gear shifts and power transmission |

Top Materials Used in the Manufacture of CNC Automotive Parts

In the world of car making, the materials used can make a big difference in how parts perform and last. We focus on using aluminum and stainless steel in our CNC machining. These materials stand up well to the tough demands of cars.

- Aluminum CNC Parts: Aluminum is light, easy to shape, and fights off rust. This makes it perfect for cars that need to go fast and use less fuel. It keeps cars safe and lasts a long time without getting heavy.

- Stainless Steel Precision Components: Stainless steel is super strong and doesn’t get rusty. This makes it perfect for the parts of a car that have to be tough and lasting. It can handle harsh weather, keeping cars running smoothly for years.

By using these top-notch materials, we make sure our car parts are the best they can be. This shows our dedication to making cars reliable and cutting-edge.

Why Choose CNC Automotive Parts Chicago for Your Vehicle

Choosing Chicago CNC machining services can uplift your vehicle’s performance. Our Chicago CNC machining services ensure quick production and precision. This precision helps boost your car’s output and efficiency. We focus on custom automotive parts design to meet your performance needs.

We are experts in enhancing vehicle performance with CNC. Our products are not just simple replacements. They are upgrades. Detailed engineering processes like precision tube cutting and robust assembly make our designs stand out. This way, each part perfectly boosts your car’s performance.

Car enthusiasts and professionals want parts that last and perform well. Our CNC vehicle performance enhancement work with this goal in mind. We use top materials and CNC techniques. This makes our products superior in the performance parts market.

We’re excited to show you the quality and impact of our Chicago CNC machining services. Designed to improve your vehicle’s capabilities, we promise excellence. Trust our experience and dedication to reach your car’s highest potential.

The Process of Custom CNC Machining for Automotive Parts

Our custom CNC process for making car parts combines high-tech equipment with careful planning. The first important step is 3D CAD model machining. This is where we make sure everything will be precise and customized right from the start.

Design and Prototyping in CNC Machining

In the beginning, our skill in CNC automotive prototyping stands out. We use the latest software to turn simple sketches into detailed 3D models. These models show every detail, like size, tolerances, and materials, making sure every prototype meets high standards.

From CAD Model to Finished Part: The CNC Machining Workflow

The path from a 3D CAD model to the final car part is complex. Once the model is ready, CAM software helps convert it to a CNC-friendly program. This guides our precision machines to cut, drill, and mill as needed.

State-of-the-art, multi-axis CNC machines greatly improve our work’s precision and speed. But our focus on detail doesn’t stop there. Every piece is checked thoroughly to match the auto industry’s strict standards. From the first prototype to full production, our whole process aims to provide top-notch results our clients can rely on.

Leading Innovations in CNC Automotive Parts from Chicago-Based Manufacturers

Since 1945, our Chicago facility has been at the forefront of Chicago machining innovations. We’ve shown how CNC technology can change the making of car parts. Our dedication and innovation are shaping the future of manufacturing.

Success stories in CNC from our facility show our excellence and precision. They highlight our skills and the trust the industry has in our automotive CNC advancements.

We’re always looking to improve car manufacturing with CNC. We invest in new technologies and people to stay ahead. Our plans include using AI and robots to make better and faster car parts.

Advancing the horizon of automotive manufacturing through innovative CNC solutions.

We keep taking on bigger projects and challenges. Our Chicago machining innovations are setting the stage for the industry’s future.

Benefits of Using CNC Machined Parts in the Automotive Sector

Automotive manufacturing has greatly improved with CNC machined parts. Reliable CNC machining makes sure car parts are of top quality and last long. Using performance CNC auto parts makes vehicles work better, ensuring safety and top performance while driving.

- Performance CNC Auto Parts: Designed for top vehicle efficiency and effectiveness, thanks to precise design and making.

- Reliable CNC Machining: Dependable production that meets strict standards, crucial for car making.

- Automotive Industry Solutions: Custom fixes for the unique challenges in the car sector, boosting utility and creativity.

Our work shows our commitment to be the best, using the latest CNC tech. We make more than just parts; we provide complete automotive industry solutions. This high-tech approach means every part, from engine blocks to gears, works flawlessly.

Performance CNC auto parts give cars an advantage because they can withstand tough conditions. This means cars are safe, work well, and last a long time. We’re proud to introduce new ideas that help the car industry grow.

Our focus on reliable CNC machining improves how car parts are made, leading to better vehicle performance. As cars and their needs change, we stay dedicated. Our goal? To provide answers that make car making and driving successful.

How to Source Quality CNC Automotive Parts in Chicago

Looking for CNC parts in Chicago means finding a top provider is key. We are dedicated to providing high-quality CNC services. Our work meets strict standards for accuracy and strength. It’s important to pick a provider known for their high-precision work to get the best parts.

Finding a supplier who gives their all to every project is crucial. Our approach includes detailed checks and following international quality standards. Thanks to our knowledge in various materials and processes, top industry leaders prefer us. They notice our cutting-edge machining skills and innovative methods.

Tips for Finding the Right CNC Machining Services Provider

To pick the top CNC services, visiting the facilities is advisable. See their technology and staff skills for yourself. Look for providers that share their process openly and offer detailed quality control docs and customer reviews.

Ensuring Quality and Precision in Your CNC Machined Parts

Quality assurance is key with precision machining providers. Ask about certifications and the checks they do while making parts. Using First Article Inspection (FAI) and checking during production ensures parts meet the required specs and sizes.

The goal is always to get the best quality and performance in auto parts. By using these tips and finding a provider that meets these standards, you’re more likely to succeed.

Conclusion

In the world of car making, having a top-notch CNC partner is vital. Our skills in Chicago machining set us apart. We focus on making the best CNC parts. This means our auto manufacturing partners get the best service possible.

This fast service helps them be more innovative and efficient. Our facilities in Chicago can handle big orders or unique parts quickly.

We’re not just any company at CNC Automotive Parts Chicago. We’re a mix of advanced tech and deep know-how. We keep improving to make sure we produce top-quality work. Our work with materials like aluminum and stainless steel keeps us ahead in the auto industry.

We’re more than a provider for manufacturers and businesses worldwide. We’re a reliable partner in creating success. As the auto industry changes, we help you stay ahead with our expertise. Our goal is to surpass the high standards of the auto industry. That’s our commitment as Chicago’s top CNC auto manufacturing partner.

FAQ

What makes CNC machining critical in automotive manufacturing?

CNC machining is vital for automotive making because it creates parts with complex shapes and precise sizes. This accuracy is needed for parts like engine components. They must be exact to work right and make the car reliable.

Why is aluminum often used in CNC automotive components?

Aluminum is chosen for CNC car parts because it’s light yet strong. It’s also easy to shape and fights rust. These qualities improve a vehicle’s performance, making aluminum popular in cars and airplanes.

Can you handle different material types for CNC automotive parts production?

Yes, we work with many materials for car parts, including stainless steel, aluminum, and titanium. We do this to meet the wide-ranging needs for making automotive parts.

What kind of quality assurance do you offer for CNC machined automotive parts?

We promise top quality by checking parts during and after making them. This ensures all CNC machined parts are precise and strong.

How does your custom CNC machining process work?

Our custom CNC process begins with a 3D CAD model that shows the size and material. This model becomes a program for CNC machines. Our advanced machines then do the cutting and milling to make precise automotive parts, following strict quality rules.

What advancements are you making in CNC automotive manufacturing?

We’re always improving our CNC tech for cars. Our advanced machines and know-how let us do complex machining. This leads to new ideas and better car parts.

How do CNC machined parts enhance automotive applications?

CNC machined parts improve cars by being very exact and making complex shapes. This means parts like engine blocks work better. We can also make parts just for a certain car’s needs.

Are there custom solutions available in your CNC machining services for the automotive industry?

Indeed, we’re experts in custom parts, making pieces just for the car industry. Whether it’s one-of-a-kind or many, our custom work pushes for new and tailored car parts.

Why should I source CNC automotive parts from Chicago?

Choosing CNC parts from Chicago means you get top-notch machining, fast service, and skilled work. Our Chicago base helps us provide finely engineered solutions that meet the needs of both local and global car markets.