Have you ever wondered how manufacturers make complex, accurate parts every time? CNC machining is the secret. It’s a cutting-edge technology changing many industries, like automotive and aerospace. This intro to CNC machining will show you how it boosts precision and productivity.

CNC machining, short for Computer Numerical Control machining, is a big improvement over old methods. It uses computerized tools to make parts designed just the way we need them. For those learning about CNC, knowing how it works is key. It’s at the heart of today’s manufacturing.

In fields where exact details matter, CNC machining is essential. Think of making parts for surgery tools or jet engines. The need for accuracy is huge. CNC machining helps industries meet these high standards, from medical to industrial uses.

So, what’s involved in this detailed process? It starts with a CAD design and ends with a perfectly made part. Every step is planned and done with care. To understand it better, click here for a full explanation.

Key Takeaways

- CNC machining is key for creating precise parts in many fields.

- The process turns CAD designs into exact machine commands.

- Knowing CNC basics is vital for exploring modern manufacturing.

- CNC’s automation boosts both speed and accuracy.

- Sectors like automotive, aerospace, and medical depend on CNC machining.

- Looking into CNC technology shows its importance in high-standard industries.

What is CNC Machining?

Computer Numerical Control, or CNC machining, changes how we make parts with computerized steps. It’s a way of making things by cutting away material from a solid block. This is directed by software. We will get into what CNC machining is and cover its main ideas and history.

Definition and Basics

CNC machining means using software to control machine movements. This lets us make detailed and accurate parts. The basics of CNC machining include using special equipment like lathes and mills. These are controlled by computers for precision, reducing mistakes, and keeping quality the same.

Historical Background

CNC machining started in the early 1950s with the creation of numerical control (NC). John T. Parsons worked with MIT on this, helping produce aircraft parts better. Over time, computer advancements have made CNC machining what it is today. It moved from simple systems to complex computer controls.

Anatomy of a CNC Machine: Components & Workflow

To use a CNC machine effectively, it’s key to know its parts and how it works. We’ll explore the main CNC machine components and the steps for operating them. This gives a clear guide for anyone setting up a CNC machine.

Main Components

A CNC machine has several important parts that work together for accurate cutting. These CNC machine components include:

- Controller: This is the CNC machine’s brain. It reads G-code and M-code commands to move the machine.

- Spindle: It holds and spins the cutting tool. This part is vital for the cutting process.

- Linear Motors: These motors move the machine’s axes. They help place the workpiece and cutting tool correctly.

- Tool Changers: They let the machine change cutting tools on its own. This boosts efficiency and flexibility.

Basic Workflow

Here’s how the CNC operational workflow typically goes, in steps:

- CNC Machine Setup: First, program the machine, load tools, and clamp down the workpiece.

- Executing the Operation: Next, the machine follows the G-code and M-code to cut.

- Monitoring and Finishing: Watch the machine work. After, check the final product’s quality.

This table shows some major CNC machine components and what they do:

| Component | Functionality | Importance |

|---|---|---|

| Controller | Interprets G-code and M-code commands | High |

| Spindle | Holds and rotates the cutting tool | High |

| Linear Motors | Drive the machine’s axes | Medium |

| Tool Changers | Facilitates automatic tool switching | Medium |

Common Techniques in CNC Machining

CNC machining has many techniques for making parts with exact shapes. Two key methods are CNC milling and CNC turning. These techniques show the great skill and accuracy of CNC machining in making things.

Milling and Turning

CNC milling uses spinning cutters to carve material away. This shapes complex parts with great detail. Key milling actions include face milling for smoothing and peripheral milling for edge shaping.

In CNC turning, the part spins while a cutter shapes it. It’s perfect for making round items like shafts and wheels. Turning can bore holes bigger or cut threads for screws.

| Operation | Technique | Application |

|---|---|---|

| Face Milling | CNC Milling | Flattening surfaces |

| Peripheral Milling | CNC Milling | Cutting along edges |

| Boring | CNC Turning | Enlarging holes |

| Thread Cutting | CNC Turning | Producing screw threads |

Drilling and Other Operations

CNC drilling makes precise holes with drill bits. This process can handle various hole sizes and depths. CNC machines also do broaching and grinding for more versatility. Broaching cuts keyways, and grinding polishes surfaces.

CNC milling, turning, and drilling show the wide skills of CNC machines. They are vital for creating accurate, complex parts in manufacturing.

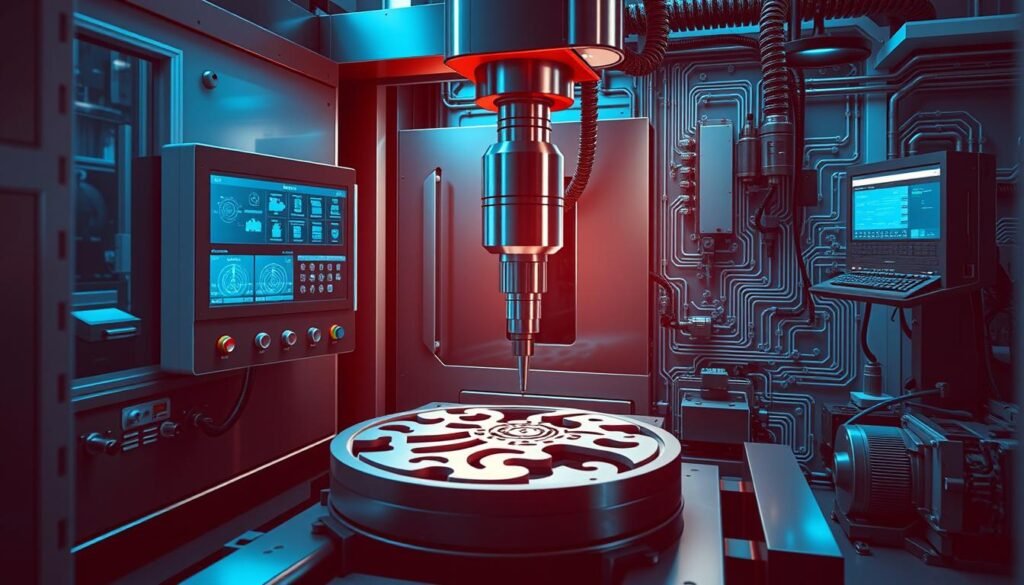

How CNC Machining Works Explained

The journey from an idea to a final product with CNC machining is both fascinating and complex. We’ll see how CNC programming, G-code in CNC, and M-code in CNC are key for precision and efficiency.

From CAD Design to Final Product

It all starts with a CAD (Computer-Aided Design) model. This model details every aspect of the product. After it’s made, CAM (Computer-Aided Manufacturing) software turns it into a CNC file. This step produces G-code in CNC, which guides the machine’s moves.

Next, we set up the CNC machine with the right tools. It then gets the CNC file, filled with G-code in CNC and M-code in CNC. These codes manage machine actions and functions. Finally, the machine crafts the material into the end product.

The Role of G-code and M-code

G-code in CNC and M-code in CNC are vital in CNC machining. G-code commands direct the machine’s physical moves, like cut paths. It’s designed to mirror the CAD model’s exact specs.

M-code helps by controlling extra functions of the machine. These functions include things like tool changes or managing coolants. Together, G-code and M-code fill a critical role in CNC programming. They provide detailed instructions for the CNC machine’s operation.

By using CNC workflow and understanding G-code in CNC and M-code in CNC, manufacturing becomes precise and efficient. For more, check out further insights on CNC machining.

Conclusion

We’ve looked closely at CNC machining, exploring its detailed processes and complex tech. This journey has shown why it’s crucial for modern making. We covered CNC machining’s history, how these machines work, and the different methods used. This all highlights the powerful abilities of CNC tech.

CNC machining brings huge benefits. It offers unmatched accuracy, more efficiency, and can handle complicated designs. This tech has transformed manufacturing by reducing mistakes and making output more consistent. Leaders like Haas, DMG Mori, and Mazak push the industry ahead with new innovations.

The future of CNC tech looks bright. With more digital tech and elements of Industry 4.0, it’s getting smarter and more connected. Things like advanced software, learning machines, and instant data analysis will boost what it can do. So, CNC machining isn’t just key for today’s manufacturing. It’s also driving us towards tomorrow’s tech frontiers.

FAQ

What is CNC Machining in simple terms?

CNC machining is a process where computers control how to cut a solid block. This creates parts that are very detailed and exact.

How does CNC machining differ from manual machining?

In manual machining, a person controls the machine. But in CNC machining, everything is run by computers. This makes the work more precise and faster.

What are the main components of a CNC machine?

Key parts include the controller, spindle, linear motors, and tool changers. These parts work together for cutting and shaping.

What historical advancements led to the development of CNC machining?

The development of CNC machining started with manual methods. It greatly improved with computer tech, making processes automated and more accurate.

Can you explain the basic workflow of CNC machining?

First, you set up the CNC machine. Next, you put in the workpiece. Then, the machine shapes the material using specific commands.

What are the primary techniques used in CNC machining?

The main methods are milling and turning. Others like drilling, broaching, and grinding can be used depending on the project needs.

How do G-code and M-code function in CNC machining?

G-code manages how machine parts move. M-code controls the operations. Together, they tell the CNC machine exactly what to do.

What is the process from CAD design to the final product in CNC machining?

First, a CAD model is made. This model is then turned into a CNC program. The machine then precisely makes the part from raw material.

Why is CNC machining highly valued in industries like automotive, aerospace, and medical?

It’s valuable because it can make parts very accurately. These exact parts are crucial for industries that have strict standards.

What advancements are anticipated in the future of CNC machining?

We expect to see more digital tech like Industry 4.0. This will enhance connection, automation, and efficiency in making things.