CNC Machining Services

Mekalite offers CNC machining services with instant quotes, high precision, and fast turnaround for prototypes or production. Order custom parts today.

Certifications ISO 9001:2015 | AS9100D | ITAR

STEP STP SLDPRT IPT PRT SAT IGES IGS CATPART X_T OBJ STL files

Our traditional CNC machining service may be a little slower than the online CNC machining service quote, but we are real people who can coordinate prices. When you need large quantities of customization, I would recommend you to choose the traditional CNC machining service quote, it will be more suitable for batch users.

Our CNC Machining Services

We offer a comprehensive range of CNC machining solutions to meet the demands of various industries and applications. Our advanced equipment and experienced engineering team ensure precision, reliability, and consistency with every order.

CNC Machining Capabilities

CNC Milling

Accurate and versatile milling for complex and custom geometries.CNC Turning

High-speed turning for cylindrical parts with tight tolerances and fine surface finishes.CNC Drilling & Tapping

Precise hole-making and thread cutting to your exact specifications.

Supported Materials

- Metals: Aluminum, Stainless Steel, Carbon Steel, Brass, Copper, Titanium, Magnesium, etc.

- Plastics: ABS, Delrin (POM), Nylon, PTFE, Polycarbonate, Acrylic, and more.

Tolerances & Maximum Part Size

- Precision: Up to ±0.01mm (0.0004″) based on your requirements.

- Maximum Size: Up to 1200mm x 800mm x 500mm for single parts (larger projects available upon request).

Surface Finishes and Post-Processing

To meet diverse functional and aesthetic requirements across industries, Mekalite offers a wide range of surface finishes and post-processing services. These options help your CNC machined parts achieve the ideal appearance, durability, and performance.

Common Surface Finishing Methods

Anodizing

Ideal for aluminum and its alloys, anodizing creates a dense oxide layer on the surface, enhancing corrosion resistance, surface hardness, and allowing for a variety of color options. Commonly used in aerospace, electronics, and consumer products.Bead Blasting

High-speed blasting with fine media removes surface impurities, resulting in a uniform matte or satin texture. Suitable for parts requiring a refined, non-reflective appearance.Plating (Nickel, Chrome, Zinc, etc.)

Electroplating applies a metallic coating to enhance corrosion resistance, wear resistance, and decorative appeal. Widely used in mechanical, automotive, and medical applications.Polishing

Mechanical or chemical polishing removes micro-imperfections, producing a mirror-like or high-gloss finish. Ideal for components with strict aesthetic requirements.Powder Coating

Electrostatic application of powder creates a strong, colorful protective layer with excellent abrasion and corrosion resistance. Suitable for outdoor equipment and machinery housings.Electropolishing

Electrochemical polishing further improves metal surface smoothness and corrosion resistance, commonly used in medical and food processing industries.Black Oxide

Mainly for steel, black oxide enhances rust resistance and provides a sleek black finish.PVD/DLC Coatings

Physical Vapor Deposition (PVD) and Diamond-Like Carbon (DLC) coatings significantly increase surface hardness, wear resistance, and corrosion protection—ideal for high-end components, tools, and molds.

Value-Added Post-Processing Services

Laser Engraving & Custom Marking

Precise part numbering, branding, or function labels for improved traceability and professional appearance.Silkscreen Printing & Spraying

Custom graphics, logos, or color markings to meet branding or functional requirements.Heat Treatment & Deburring

Enhance mechanical properties and ensure all parts are free from sharp edges or burrs for safety and easy assembly.

Performance & Application Guidance

Each surface finish not only affects the look of your part, but also impacts key properties such as corrosion resistance, wear resistance, friction, and service life. For example:

Anodizing is best for aluminum parts needing color and corrosion resistance.

PVD/DLC coatings are recommended for components requiring extreme hardness and low friction.

Polishing is ideal for medical or electronic parts demanding a flawless appearance.

Powder coating is excellent for outdoor or heavy-duty applications.

This content provides clear, professional guidance on surface finishes and post-processing, helping customers make informed choices and highlighting your technical capabilities.

CNC Turning Services

Instant quotes on custom metal and plastic turned parts | Quick-turn prototypes and production parts in days | Free standard shipping on all US orders | International prototype pricing includes tariffs | ISO 9001:2015, ISO 13485, IATF 16949:2016, AS9100D certified. ITAR registered.

Online CNC Machining Services

Online CNC machining services for rapid prototypes and production parts in metals or plastics. Get instant quotes today, and order your custom CNC machined parts at a better price.

DLC Coating Services

Boost part performance with durable, low-friction DLC coatings! Contact us now for tailored solutions!

PVD Coating Services

Mekalite’s PVD coatings enhance components with superior hardness, wear resistance, and corrosion protection. Ideal for CNC machining, aerospace, and automotive, our thin-film coatings ensure low friction and precision using advanced vacuum deposition. Tailored to your needs with strict quality and fast turnaround, Mekalite boosts performance. Contact us today.

Materials & Capabilities

At Mekalite, we are equipped to handle a broad spectrum of machining materials and project requirements, ensuring you get precision-engineered parts every time.

Materials We Machine

We support a wide variety of materials to meet your application needs, including but not limited to:

- Aluminum (6061, 7075, etc.)

- Stainless Steel (303, 304, 316, etc.)

- Brass

- Copper

- Titanium

- Plastics

- ABS, POM (Delrin), PC (Polycarbonate), Nylon, PTFE, and more

If you have specific material requirements or need advice on material selection, our engineering team is ready to assist.

Machining Capabilities

- Tolerances: Achievable up to ±0.01mm (0.0004 inch) depending on material and part geometry

- Part Sizes:

- Minimum: As small as 3mm in features

- Maximum: Up to 1200mm in length (depending on equipment and complexity)

- Quantity Flexibility: From single prototype units to large batch production runs

We cater to both high-precision prototypes and mass production with equal expertise.

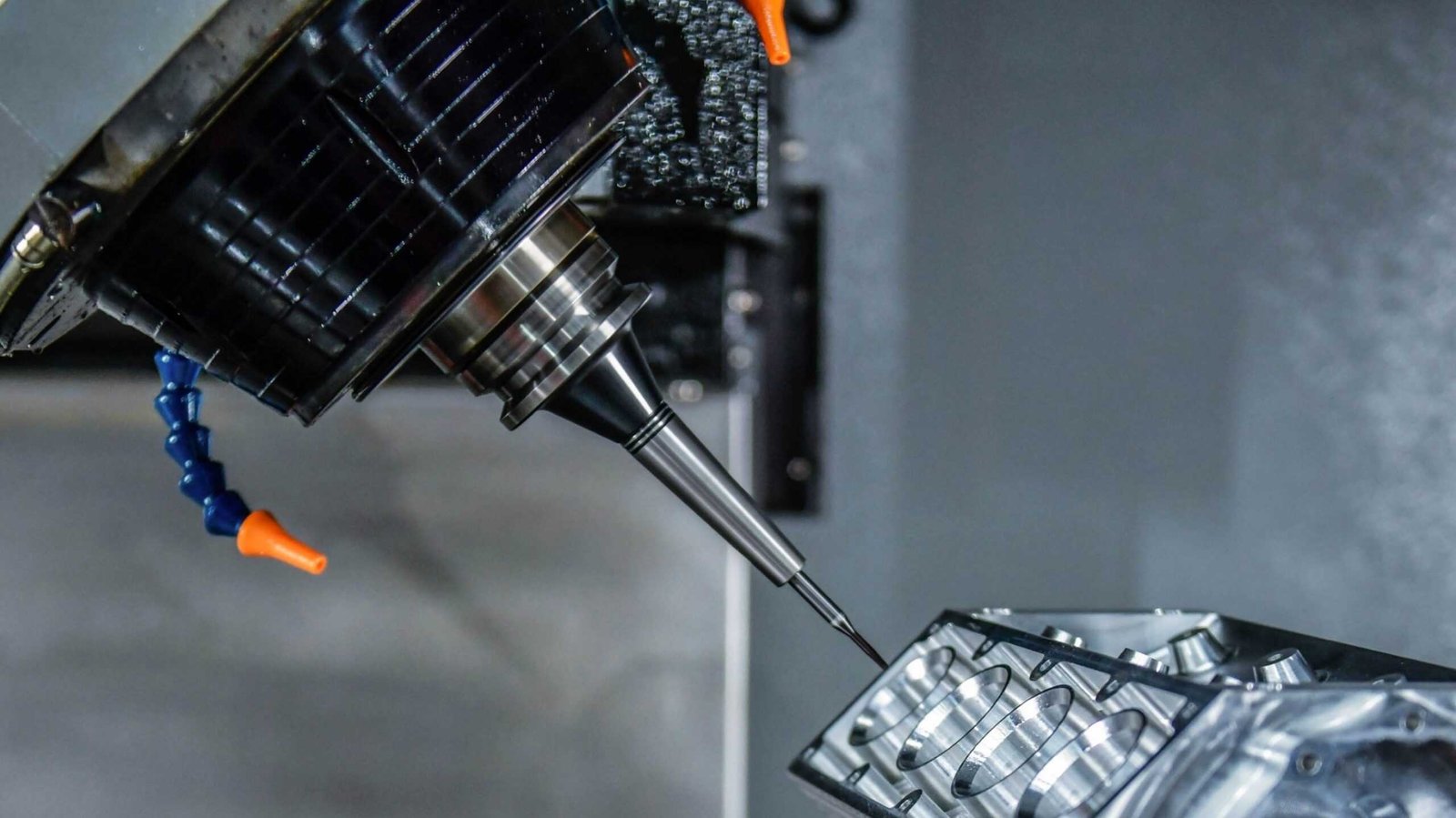

Our Equipment

To guarantee top-quality results and high efficiency, we operate a modern workshop with advanced machinery, including:

- High-speed CNC milling machines

- Precision CNC lathes

- 3-axis, 4-axis, and 5-axis machining centers for complex geometries

- Wire EDM and grinding equipment

- CMM (Coordinate Measuring Machine) for quality inspection

- Auxiliary tools for thread cutting, surface finishing, and assembly

Regular calibration and maintenance ensure that our equipment consistently delivers accurate, repeatable results for all your custom parts.

Quality Assurance and Testing Capabilities

We are committed to delivering CNC machined parts that meet the highest standards of quality and performance. Each order undergoes strict quality control at every stage of the manufacturing process to ensure your satisfaction.

Advanced Inspection Equipment

- Coordinate Measuring Machine (CMM)

- Digital Calipers & Micrometers

- Height Gauges

- Surface Roughness Testers

- Hardness Testers

- Optical Projectors

- More specialized measurement tools to verify accuracy and consistency

Rigorous Quality Control Process

- Incoming Material Inspection: All raw materials are checked and verified for quality and compliance before production.

- In-Process Inspection: Regular inspections are conducted during machining to monitor critical dimensions and surface finish.

- Final Inspection: Every part undergoes thorough measurement and visual checking before packaging and shipment.

- Sample Retention and Traceability: Inspection reports and sample retention guarantee each order can be traced and reviewed upon request.

Certifications

We operate under a strict quality management system and maintain certifications to guarantee reliability:

- ISO 9001:2015 Certified

- RoHS Compliant (if applicable)

- Specific industry certifications available upon request

With our state-of-the-art inspection facilities and experienced quality assurance team, you can trust us to deliver CNC machined parts that consistently meet your specifications and industry standards.

Why Choose Our CNC Machining Services

Our CNC machining services deliver unbeatable speed, precision, and flexibility to help you succeed with every project. Here’s what sets us apart:

Fast Response & Delivery

Get your CNC machined parts delivered as quickly as 1-3 days with our rapid production and efficient logistics.High Precision Manufacturing

We achieve tight tolerances and superior surface finishes to meet demanding industry standards for every part.Wide Range of Materials & Finishes

Choose from a comprehensive selection of metals, plastics, and advanced surface treatments to meet your specific application needs.Prototyping to Mass Production

From single prototypes to large-scale production runs, our flexible production capability covers all your requirements.Reliable Quality Assurance

Rigorous inspections, advanced measuring instruments, and ISO-certified processes ensure complete quality you can trust.Worldwide Delivery

We serve clients around the globe, arranging shipping solutions for fast and safe delivery to your location.

Experience the difference with our professional CNC machining services—tailored to your needs, delivered with speed and reliability.

Hear from our clients

Our clients love working with us, just read what they have to say!

Frequently Asked Questions (FAQ)

What payment methods do you accept?

We accept bank transfers (T/T), PayPal, and major credit cards. Other payment methods may be available upon request.

How long does it take to receive my CNC machined parts?

Standard lead time is typically 3-7 business days depending on part complexity and quantity. Expedited production and delivery are available for urgent orders.

How do you ensure the confidentiality of my designs?

We treat all customer information and files with strict confidentiality and can sign non-disclosure agreements (NDAs) upon request.

Do you offer quality inspection reports?

Yes, we provide full inspection reports and certificates of compliance with all orders, upon request.

What if my parts arrive damaged or do not meet specifications?

Please contact us immediately. We will review the issue and, if confirmed, offer free replacements or refunds as per our quality guarantee policy.

Can I request a quote before placing an order?

Absolutely. Simply upload your CAD drawings or specifications via our website for a fast, free, and no-obligation quotation.

Do you provide international shipping?

Yes, we ship worldwide using reliable couriers (DHL/UPS/FedEx, etc.) and provide tracking information for all deliveries.