In New York, we lead in advanced manufacturing and take pride in our precision fabrication. Our CNC sheet metal fabrication hub shows our commitment to excellence. With over 15 years of CNC design and operation experience, we deliver a wide range of services. These are designed to meet our client’s specific needs. From making complex metal parts to offering various CNC services, we ensure a smooth process from design to the finished product.

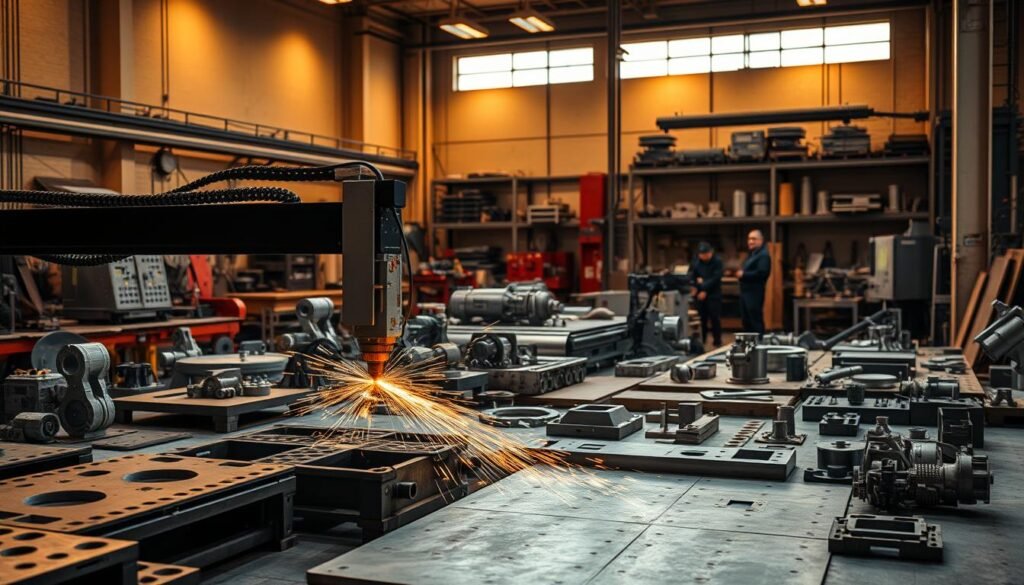

We are known for quickly making products, thanks to our 130,000 square foot facility packed with the latest technology. This includes CNC fiber laser, CO2 laser, and CNC router systems. By working with us, you join a long history of technical skill that began in 1946. We create reliable, high-quality products for different fields.

Key Takeaways

- Expertise in precision CNC sheet metal services, adhering to the highest standards of advanced manufacturing in New York.

- Emphasis on rapid production without compromising quality, utilizing state-of-the-art CNC technology.

- Over 15 years of specialized experience in CNC design and operation, ensuring reliability and technical precision.

- Dedication to providing swift and detailed manufacturing processes, from concept to completion.

- Extensive facility boasting advanced industry-leading equipment for varied CNC services and custom fabrication needs.

Overview of CNC Sheet Metal Services in New York

We lead in offering CNC sheet metal services in New York. Our goal is to meet the changing needs of the manufacturing sector. We focus on precise, custom metal fabrication in each project.

Custom Metal Parts Manufacturing

We excel in making custom metal parts. From start to finish, we ensure high-quality in every piece. Our work is key for industries needing unique, long-lasting parts.

CNC Services Across Various Materials

We’re skilled in handling many materials. Our services cover mild steel, stainless steel, brass, copper, and aluminum. We meet specific industry needs with great accuracy.

Rapid Production and Design Implementation

Our technology allows for quick production without losing quality. We have efficient processes to turn designs into real products fast. This helps businesses keep up in quick-moving markets.

We have deep knowledge and top-notch equipment. We meet your custom metal fabrication needs at the highest standard. Looking for detailed parts or strong metal structures? Our New York site is ready to deliver quickly and excellently.

The Role of Laser Cutting in Precision Metal Fabrication

In New York’s dynamic manufacturing landscape, laser cutting services have changed the game. This technology is known for its precision and efficiency. It’s crucial in making components that are both accurate and smooth, which are necessary for today’s uses.

Versatility in Material Handling

Laser cutting is amazingly versatile. It can handle lots of different materials like mild steel, stainless steel, aluminum, copper, and brass. This means we can help all sorts of clients, from construction to custom designs, making it vital for industrial laser applications.

Benefits of Laser Cutting for Rapid Prototyping

The need for rapid prototyping is perfectly met by laser cutting. It cuts down production time without losing quality. This is great for quick updates based on tests, helping innovation.

Applications Across Industries

Lots of sectors like automotive, aerospace, electronics, and healthcare benefit from laser cutting. It gives them the precise cutting they need, whether for small electronic parts or big aerospace pieces.

As our knowledge in laser cutting services grows, so does the range of its uses. This helps us improve how we work and develop products.

| Industry | Material | Application Example |

|---|---|---|

| Aerospace | Titanium | Aircraft panels and structural components |

| Automotive | Aluminum | Engine components and decorative trims |

| Electronics | Copper | Printed circuit boards and enclosures |

| Healthcare | Stainless Steel | Surgical instruments and implants |

The Advantages of CNC Machining in Rapid Fabrication

We use 3 axis CNC machining, 4 axis CNC machining, and 5 axis CNC machining to reach excellence in manufacturing. These methods boost our precision and let us make more complex parts. This is especially important for aerospace manufacturing. With these advanced processes, we make sure every piece meets the top quality and precision the aerospace and defense fields need.

3, 4, and 5 axis CNC machining have a special advantage. They can handle complex designs and shapes that other machines can’t. This is key for aerospace parts where every tiny detail matters. Plus, these machines set up faster and use materials more efficiently. This cuts down on waste and saves money.

From prototype to production, CNC machining makes things smooth. It reduces errors and speeds up delivery. This is crucial for meeting the quick pace of aerospace and defense projects. Our CNC machining gives consistent, exact results. This is why it’s so valuable in making critical aerospace parts.

CNC machining’s role in aerospace and defense is huge. Aircraft and spacecraft parts need perfect precision. Any small mistake can cause big problems. Our high-tech CNC machines keep our commitment to top-notch quality. They meet the strict standards required in aerospace manufacturing.

Precision-Crafted CNC Sheet Metal Services

We excel in CNC precision metal crafting. Our work stands out for its quality and detailed attention. Our techniques shine in our top-notch facilities, making us industry leaders in New York. We meet client needs with precision, showing our dedication to excellence in every metal piece.

From architectural designs to electronic parts, our CNC crafting meets all standards. We’re in New York, giving us a big advantage. Thus, we offer high-quality, reliable services for various client needs.

We get the needs of modern industries, from aerospace to cars and machines. Our work involves careful planning, exact work, and strict quality checks. This way, we provide unmatched CNC metal crafting tailored to client requirements.

We keep our lead by using the latest technologies and methods. This constant improvement means our clients get the best solutions for their projects.

Custom Sign Fabrication: From Concept to Completion

Our company goes beyond just making signs. We create a key part of a brand’s identity. Our custom signs show our dedication to quality and new ideas. Using advanced design tools and custom laser cuts, we make each project shine.

We offer full services for making signs. This includes designing and making them with a lot of care. Our team uses their years of knowledge to make even complex designs real. This way, from start to finish, everything goes smoothly, matching our clients’ goals perfectly.

We make a wide range of custom laser cut signs from strong metals to pretty acrylics. This makes them last long and look good. Our signs are more than just signs; they’re a bold way to show a brand’s message.

We’re here to make your ideas come true with signs that are both useful and stylish. These signs will help your brand stand out in any market.

Conclusion

In our fast-changing world of manufacturing, we’re proud of our deep New York CNC expertise. Our history is built on consistently delivering top-notch manufacturing solutions. We use cutting-edge technology and deep knowledge to meet our clients’ needs.

Those in the manufacturing industry and business leaders benefit from our wide range of services. We aim to not only meet but surpass expectations. Every project showcases our technical excellence and dedication to quality.

We’re committed to improving our methods and setting new standards in the industry. We invite you to be part of this journey towards excellence. Together, we’re shaping the future of metal fabrication with expertise and advanced technology.

FAQ

What CNC sheet metal services do you offer in New York?

We offer many CNC sheet metal services. These include making custom metal parts, cutting, welding, polishing, and more. We can handle a range of materials like mild steel, stainless steel, brass, copper, and aluminum. Our goal is to bring your design to life.

How does your rapid production process work?

Our rapid production relies on advanced CNC technology. We use fiber laser, CO2 laser, and CNC router machines. These tools help us quickly move from design to finished part. We focus on fast design execution to speed up production while keeping quality high.

Can you handle rapid prototyping with your laser cutting services?

Yes, we can. Our laser cutting is perfect for fast prototyping. It offers quick turnaround times and precise accuracy. This means we can make changes quickly to ensure the final product is just right.

What materials can you process with your laser cutting services?

We can cut a wide range of materials. Our laser cutting services handle mild steel, stainless steel, brass, copper, and aluminum. We can work with these materials in different shapes like plate, tube, and pipe.

What is the significance of using 3, 4, and 5 Axis CNC Machining?

Using 3, 4, and 5 Axis CNC Machining lets us make very precise parts. It’s very important for industries like aerospace and defense. These machines allow us to create complex designs with tight tolerances. They also help us move from prototypes to full production smoothly.

How do you ensure quality control in your CNC machining services?

Quality control is key to our work. We maintain high standards from design to production. We constantly monitor and test our work to make sure it meets our clients’ needs and the top industry standards.

What custom sign fabrication services do you offer?

We make various custom signs. Our services include laser cut steel signs, elegant company reception signs, and unique PVC and wood plaques. We support our clients from the design phase to the final product.

How do you cater to the specialized needs of different industries?

With over 15 years of experience, we have the skills to meet specific industry needs. We know what the medical, aerospace, defense, and other sectors require. Our team customizes our services to meet these exact needs.