Did you know the world’s largest manufacturing building is near Seattle? It’s over ninety acres and makes parts for big names in the industry. This shows how big the chance is for Aerospace CNC solutions in Washington.

Local makers are always looking to do better. They use automation, precision, and speed to meet tight deadlines. At Mekalite, we help by offering top-notch CNC machining. We’re based in Shenzhen and make custom parts for companies all over.

Key Takeaways

- Seattle is home to vast aerospace manufacturing facilities that require precise machining.

- Tight delivery targets and high production runs fuel CNC demand.

- Advanced automation boosts speed and accuracy on every project run.

- Global competition encourages continual upgrades in technology and methods.

- Mekalite supports these needs with custom part production and technical expertise.

Understanding Washington’s Aerospace Manufacturing Landscape

The aerospace industry in Washington is thriving. It was shaped by aviation pioneers who made key discoveries. These discoveries are the foundation of today’s Seattle manufacturing sector.

The area has a vast network of suppliers and ports. This makes it easier to move products around. It helps us meet our goals of quick and efficient production.

We manage big orders for aircraft parts with care. We focus on smooth logistics and precise work. Our use of Advanced CNC machinery lets us adapt to new demands while keeping quality high.

Our work brings together engineers, machining experts, and distributors. We keep improving our methods. This ensures Washington remains a top place for aerospace innovation.

Emerging Trends in CNC Machinery

CNC precision engineering is evolving fast with new software tools. We’re on the edge of big changes in automation, collaborative robots, and real-time analytics. At Mekalite, we quickly adapt with advanced equipment and skilled engineers.

From Manual to Automated

Manual setups needed constant watch. Now, automated milling and multi-axis machining cut down on errors and speed up production. Our method uses digitized controls and sensors for quick and precise work.

Enhancing Production Efficiency

We use these new methods to save costs, shorten production times, and keep quality high. NSF-funded research shows more progress in robotics and software. Our CNC precision engineering model allows for quick changes, keeping output steady even with market changes.

| New CNC Technologies | Key Benefits |

|---|---|

| Collaborative Robots | Improved safety and faster workflows |

| Real-Time Data Analytics | Reduced downtime and predictive maintenance |

| Advanced Software Integration | Precise replication of complex parts |

Aerospace Giants Shaping the Future of Aviation

Leading companies in Seattle are pushing the limits of air travel. They’re working on new aircraft designs and engines. For example, the Vy 400 is an experimental plane that shows their big investment in new ideas.

They use lightweight materials and powerful engines. This means they need parts that can handle a lot of stress. Aerospace CNC solutions help make these parts with high precision and less waste.

Our team knows how important quality and quantity are in aviation. Saving weight means better performance. So, we focus on top-notch tools and machines. We stand ready to meet the demands of modern flight. Aerospace CNC solutions are key to meeting these needs.

The Significance of CNC Precision in Aircraft Assembly

We focus on making every part the same. Small differences can be big problems. So, we use top-notch CNC machines and check everything carefully to follow strict safety rules.

Tight Tolerances for Safety

Every tiny detail counts when making safe planes. We use CNC to make sure each part fits perfectly. This careful work helps avoid problems and meets important safety rules.

Reducing Production Bottlenecks

We work fast to make parts and put planes together quickly. This way, we keep quality high and meet deadlines. Our quick setup and smooth programming help us stay on track.

| Key Benefit | Impact |

|---|---|

| Consistent Accuracy | Boosts Overall Safety |

| Swift Production | Keeps Deadlines in Check |

| Minimal Downtime | Enhances Output Capacity |

How Seattle’s Tech Ecosystem Supports CNC Innovation

The region’s lively research culture is a big plus for us. Tech giants and startups bring new tools and ideas to the Seattle manufacturing sector. Our engineering team keeps up with the latest in software, data, and design.

This leads to better production and higher accuracy. It’s a place where new ideas can really take off.

We work with experts in AI and robotics. These partnerships make us more competitive and improve quality. By supporting startups and testing prototypes, we see new, specialized CNC applications.

For more on innovative services, check out our top CNC machining services in the USA. The mix of tech visionaries and skilled machinists keeps Washington’s industry leading.

| Key Element | Impact on CNC |

|---|---|

| AI Integration | Helps optimize toolpaths and minimize errors |

| Startup Partnerships | Accelerates prototyping for new designs |

| Robotics Advancements | Enhances speed and consistency |

Key Materials and Alloys for Aerospace Components

We work with many metals for modern aircraft in the Washington aerospace industry. We focus on precision and durability. Our team at Mekalite uses multi-axis machining solutions for complex materials. This ensures every part is made with exact measurements.

Aluminum Alloys for Lightweight Strength

These alloys make flight structures light but strong. We adjust spindle speeds and feed rates for smooth surfaces. This is important where wear resistance matters.

Advanced Composites for Durability

We use special tools and cutting strategies for fiberglass, carbon fibers, and more. Fatigue resistance is key for these materials. It helps them perform well over time in aerospace travel.

Titanium’s Role in High-Temperature Regions

Titanium is vital in areas like engines that get very hot. We use controlled milling to protect titanium’s strength. This approach helps meet strict safety standards in the Washington aerospace industry.

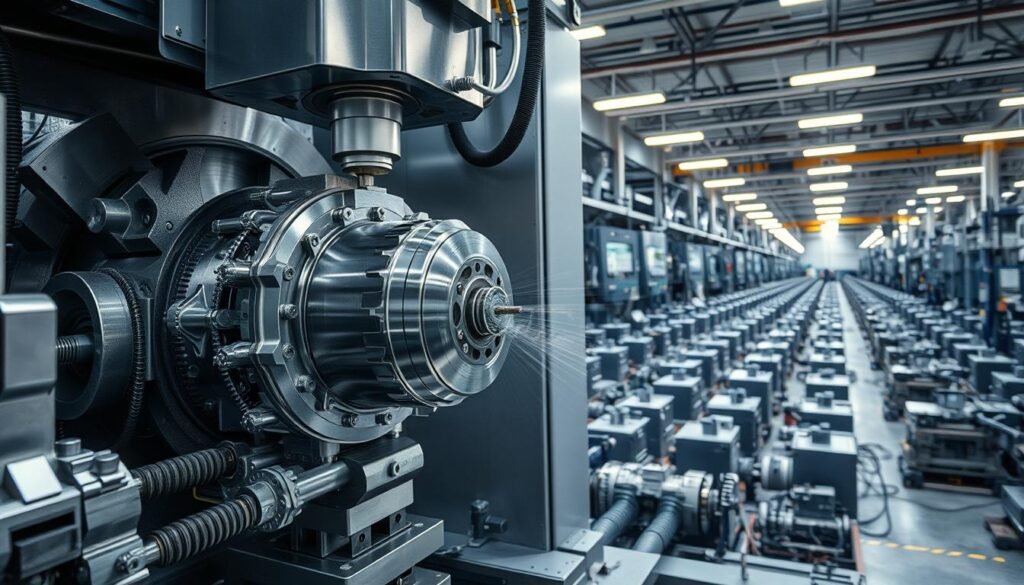

Automation and Robotics in Washington’s CNC Facilities

We use robotics and automated systems to keep our operations running almost all the time. Mechanical arms handle materials with perfect consistency. Tool changers quickly switch tasks, boosting production on every shift.

Real-time cameras catch small details that help us manage quality. This reduces errors before they become big problems.

We also use Advanced CNC machinery to improve precision and productivity. Our process includes a smooth flow of conveyors that feed components into robotic stations. This setup lets us quickly adapt to changing demands while keeping quality high.

Aerospace CNC solutions get even better with computer vision. It quickly spots imperfections for quick adjustments.

We work with Electroimpact and other leaders to keep our production lines up-to-date. Our team uses these technologies to meet high expectations and keep production strong. This approach helps us complete projects smoothly without losing quality or speed.

| Automation Tool | Purpose | Value |

|---|---|---|

| Robotic Arms | High-precision loading | Steady throughput |

| Automated Tool Changers | Swift task swaps | Fewer production delays |

| Vision Systems | Real-time checks | Lower rework rates |

Leveraging Data Analytics for Enhanced Machining Quality

Data analytics is key in CNC precision engineering. It helps us track cutting angles and tool wear in real-time. This lets us make quick changes to improve quality.

This method ensures consistent part quality, even when aerospace demands are high.

Real-Time Monitoring

We use sensors and advanced software to catch temperature or vibration changes. This live data reduces inspection time and improves surface finishes. It helps us meet precise tolerances for every part.

Operators can quickly respond to any issues that come up.

Predictive Maintenance

We analyze data logs to predict when tools will wear out. This way, we can replace them before they break down. It prevents unexpected downtime and keeps machines running smoothly.

We use insights from research to improve our analytical tools. For more on CNC craftsmanship, check out this resource. Mekalite leads in optimized part machining thanks to our data-driven approach.

- Fewer defective parts through honest metrics

- Lower operational costs with timely alerts

- Consistent throughput across large production runs

| Data Metric | Primary Advantage |

|---|---|

| Cutting Force | Controls surface finish quality |

| Tool Wear | Extends component lifespan |

| Temperature Range | Maintains accuracy under high-speed cuts |

Workforce Development: Training the Next Generation of Machinists

The demand for skilled machinists in Seattle’s manufacturing sector is growing. Our team offers specialized programs and hands-on training. This sharpens technical skills.

We partner with local community colleges. This brings fresh talent into apprenticeships. These programs focus on real-world problem-solving and mastering CNC technology.

Mekalite is committed to ongoing learning. This keeps our machinists up-to-date with the latest techniques. It opens up more career paths, improves skill retention, and raises safety standards.

Working together with schools, aerospace companies, and industry experts helps. It ensures a steady flow of skilled workers in Seattle’s manufacturing sector.

| Key Initiative | Benefits |

|---|---|

| Apprenticeship Collaboration | Hands-on industry immersion for emerging machinists |

| Technical Program Alignment | Tailored curricula matching evolving CNC standards |

| Continuous Professional Development | Ongoing skills expansion to match new equipment capabilities |

Sustainability Initiatives Fueling Green Manufacturing

We focus on using resources wisely in our production. Our teams work with grants to develop new green technologies. This helps us reduce waste and lower our carbon footprint.

Eco-Friendly Materials

We use bio-based resins and recyclable alloys to protect the environment. Our goal is to source materials responsibly, cutting down emissions. This approach supports a circular economy and makes aerospace CNC solutions more durable and waste-free.

Energy-Efficient Equipment

We choose low-energy automated tools for our machines. Special software helps us avoid waste and improve efficiency. Thanks to the National Science Foundation, we’re always looking to make our operations cleaner and more reliable.

Regulatory Factors Influencing CNC Growth in Seattle

Federal, state, and local rules push for precision and reliability. They set quality standards that help in traceability. This leads to new investments in automated CNC systems.

Following these rules is key for the Washington aerospace industry. It helps reduce errors and keeps machinists safe. We focus on using advanced CNC processes that are good for the environment and keep things moving fast.

Upgrading equipment is often needed to meet local emissions goals. Our team knows that new machines can lead to better work. This means we can work faster and more accurately, helping the Washington aerospace industry grow. We stick to international standards and safety rules, showing our commitment to reliable solutions.

| Key Standards | Primary Focus | Result for CNC |

|---|---|---|

| Federal Regulations | Quality and Safety | Ongoing Process Improvements |

| AS9100 | Unified Requirements | Enhanced Automation and Traceability |

| Local Environmental Rules | Emission Control | Equipment Upgrades and Eco-Efficiency |

Partnering With Local Suppliers for Streamlined Production

We work closely with local experts to make each production cycle better. At Mekalite, we believe in local supply chains that meet project needs quickly. This way, we can make changes fast and keep everything running smoothly.

Our goal is to work well with the Seattle manufacturing sector. We focus on speed and teamwork.

Shorter Lead Times

We connect resources quickly and keep things clear. Local networks help parts move fast, cutting down on delays. This means critical parts arrive on time, avoiding hold-ups.

Our use of Advanced CNC machinery benefits from local materials. These materials arrive early, helping us meet urgent orders.

Improved Collaboration

We do our best when suppliers and engineers talk directly. Face-to-face talks help solve problems early. This builds trust and ensures quality and quick responses.

Our global vision meets local know-how. This creates a reliable supply chain based on strong partnerships.

Challenges Facing Washington’s CNC Sector

Raw material costs can be unpredictable, and aerospace designs are very complex. The global market is also very competitive. We face a shortage of skilled workers, making it hard to adopt new technologies.

Yet, we keep pushing forward. We work with schools and investors to bring new ideas to life. This helps us stay ahead in the game.

- Soaring raw material prices

- Intricate part requirements

- High-stakes global rivalry

- Shortage of skilled machinists

Staying agile with targeted investments allows us to drive forward with advanced manufacturing breakthroughs.

We think we can overcome these challenges with the right Aerospace CNC solutions. Venture capital is key in helping us move forward. It keeps us at the top of our game.

Mekalite is ready to face these challenges head-on. We combine the latest technology with skilled workers for top-notch results. Our commitment to research and flexibility keeps us growing strong in this fast-paced field.

Future Outlook: Emerging CNC Technologies on the Horizon

Our industry is seeing fast changes with new manufacturing breakthroughs. We aim to break new ground in CNC precision engineering. This will open up new ways to make complex products.

We see a future where old and new methods come together. Hybrid techniques will mix additive processes with traditional machining.

Additive Manufacturing Integration

We’re using research to blend 3D printing with classic milling. This method speeds up design and makes detailed parts. It shows our commitment to innovation at Mekalite.

Cloud-Driven Machinery

We link our Advanced CNC machinery to the cloud for instant analytics. This setup allows for remote monitoring and updates. It makes production smoother and more efficient.

Our teams use predictive controls and feedback loops to improve machine performance. This keeps our operations running smoothly.

| Technology | Key Advantage | Potential Growth |

|---|---|---|

| Hybrid Additive | Combines layering with milling | Elevates part customization |

| Cloud Connectivity | Enables remote access | Reduces downtime |

| Predictive Controls | Analyzes performance data | Improves resource efficiency |

Partner With Mekalite for High-Quality CNC Solutions

We offer advanced engineering to markets worldwide, focusing on aerospace and other key sectors. Being a Shenzhen CNC manufacturer shows our dedication to precision and innovation. We stay up-to-date with changing needs, ensuring every project meets high standards.

Check out our CNC machining services in China to see how we improve production for better accuracy and durability.

We offer a flexible approach for various production needs, from quick prototypes to big orders. Our long experience helps us meet specific project goals while keeping quality consistent.

Global Expertise

We work with partners globally who need high standards. Our technicians work closely with aerospace leaders, sharing knowledge to improve performance at every stage.

Advanced Manufacturing Equipment

We use the latest CNC mills and lathes for precise builds. We ensure quality control at every step, with thorough inspections.

Custom Part Production for Varied Industries

Mekalite solutions drive innovation in aerospace, automotive, and electronics. Our teams quickly adapt to new needs, ensuring quality and speed.

Choosing Mekalite solutions means partnering with a reliable company focused on precision, reliability, and expert advice.

Conclusion

Washington’s aerospace sector is looking up. Our manufacturers are getting better at making things faster and more precise. This means safer flights and more room for new ideas.

We’re proud to help make these advancements happen. Our global knowledge and engineering skills ensure top-notch quality. We’re all about being quick, using the latest tech, and making things better with data.

Mekalite is here to be a key player in aerospace CNC solutions. We know how important it is to meet deadlines and high standards. Let’s explore new opportunities together in Seattle’s leading aerospace market.

FAQ

How are aerospace leaders in Seattle driving the need for advanced CNC solutions?

Companies like Boeing push for new designs that need precise parts. This demand, along with global competition and tight deadlines, boosts the need for automated CNC solutions. These solutions must meet strict standards and deliver quickly.

Why is Industry 4.0 becoming a central theme in Washington’s aerospace manufacturing?

Industry 4.0 brings together automation, data analysis, and digital twin tech. It helps aerospace makers improve workflows and quality. Local CNC shops use robots and predictive maintenance to boost productivity and meet aerospace standards.

Which materials benefit most from advanced CNC machining techniques?

Aerospace often works with aluminum alloys, advanced composites, and titanium. These need special tools and processes for strength. Multi-axis milling and CNC lathes ensure these parts are safe and light.

How does integrated automation reduce operational downtime in CNC facilities?

Automation, like tool changers and robotic arms, keeps production going. It reduces manual work, ensuring parts are consistent and errors are low. This makes CNC facilities run smoothly and efficiently.

In what ways do data analytics and predictive maintenance support aerospace CNC projects?

Monitoring cutting forces and tool wear in real-time helps spot issues fast. Predictive maintenance uses sensors to predict problems, cutting downtime. This ensures quality meets strict aerospace standards.

What role does sustainability play in Washington’s aerospace CNC sector?

Our area focuses on eco-friendly practices like using bio-based resins and recycling alloys. CNC shops use software to reduce waste, saving costs and protecting the environment.

How is Seattle’s local workforce supporting future growth in CNC manufacturing?

Vocational training and apprenticeships provide skilled machinists. This workforce is ready for complex tasks, ensuring aerospace parts are made with precision.

Why does partnering with Mekalite strengthen aerospace production strategies?

Mekalite brings global expertise and top-notch equipment for aerospace needs. With quality control, engineering support, and experience, we meet Washington’s aerospace demands.