PVD is an acronym for Physical Vapor Deposition. PVD coating is defined as a variety of thin film deposition techniques whereby a solid material is vaporized in a vacuum environment and deposited on substrates as a pure material or alloy composition coating.

As the process transfers the coating material, whether as a single atom or on the molecular level, it has the capacity to provide coatings of an extremely pure and high-performance nature. For a considerable number of applications, such coatings have been demonstrated to be preferable to other methods. PVD Coatings are of paramount importance in a wide range of technological devices, including but not limited to microchips, semiconductors, durable protective films, optical lenses and solar panels. Indeed, PVD Coatings are instrumental in ensuring the optimal performance of the final product in each of these technological devices. The PVD process has been demonstrated to provide a solution to a variety of coating-related challenges, including the requirement for extreme thinness, purity, durability, or cleanliness.

The substance under discussion is employed in a variety of industries, including, but not limited to, the following:

- Optical applications, ranging from eyeglasses to self-cleaning tinted windows

- Photovoltaic applications for solar energy

- Device applications, such as computer chips, displays and communications

- Functional or decorative finishes, from durable hard protective films to brilliant gold, platinum or chrome plating

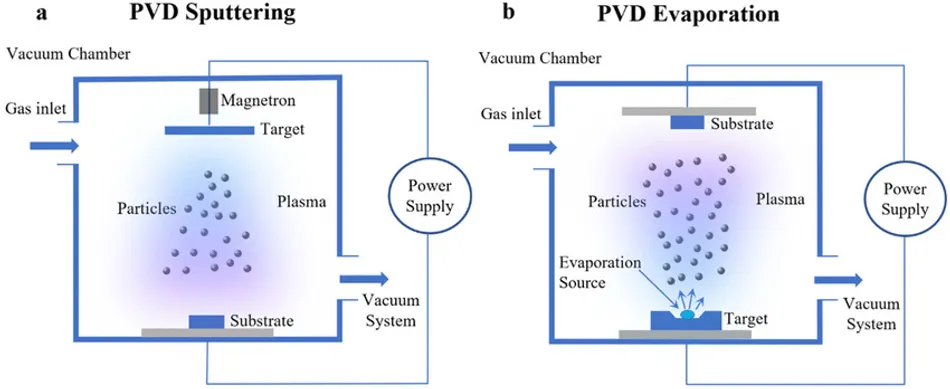

The two most common physical vapor deposition coating processes are known as sputtering and thermal evaporation. Sputtering can be defined as the process of subjecting a coating material, hereafter referred to as the ‘target’, to a high-energy electrical charge, resulting in the ejection of atoms or molecules from the target’s surface. These atoms or molecules are then deposited on a substrate, such as a silicon wafer or a solar panel. Thermal evaporation is a process that involves the application of heat to a coating material in a high vacuum environment, thereby elevating its boiling point. This process initiates the formation of a vapor stream within the vacuum chamber, which subsequently condenses on the substrate.

Get a quote for PVD Coating services

What Makes PVD Coatings Highly Durable, Corrosion and Scratch Resistant?

The ability to apply coatings at the atomic level using PVD enables control of the structure, density and stoichiometry of the films. The employment of specific materials and processes enables the customisation of the physical vapour deposition (PVD) film, allowing the desired attributes to be tailored, including but not limited to hardness, lubricity, and adhesion.

These coatings have been demonstrated to reduce friction and provide a barrier against damage. The applications for these coatings are continually expanding. In a variety of sectors, including but not limited to aerospace, automotive, defence and manufacturing, there is a requirement for products which exhibit durability over an extended period.

This variety of physical vapour deposition coating has been shown to possess a high degree of resistance to tarnishing and corrosion. This property renders the coating suitable for utilisation in a broad spectrum of decorative applications, including finishes that exhibit colour permanence. The process of physical vapour deposition (PVD) of gold or platinum coatings on watch dials and other components has been shown to produce finishes of a high lustre. This has been demonstrated to render the timepieces highly resistant to abrasion, thereby significantly extending their durability.

Titanium nitride and analogous coatings provide aesthetically pleasing finishes that are also highly resistant to corrosion and wear. The utilisation of these materials in household items, including but not limited to door handles, plumbing fixtures, and marine fixtures, as well as machining tools, knives, and drill bits, is a testament to their widespread application. The resultant coatings exhibit superior hardness, durability and resistance to wear.

Are PVD Coatings Safe?

Physical vapour deposition (PVD) is an environmentally friendly technique, otherwise referred to as “plating”, which significantly reduces the amount of toxic substances utilised, managed and disposed of, in comparison to other “wet” processes that involve fluid precursors and chemical reactions, which achieve the same result. The surgical and medical implant industry has identified Physical Vapor Deposition (PVD) as the optimal technology for the production of coatings that are characterised by their extreme purity, cleanliness and durability.

How are PVD Coatings Applied?

It is important to note that, irrespective of the specific application process (i.e. sputtering or thermal evaporation), both physical vapour deposition processes are fundamentally high vacuum techniques. In both cases, the source material is vaporised to form a plasma of atoms or molecules, which are then deposited on a wide range of substrates. The process is conducted within a high vacuum chamber, where the pressure is reduced to a range of 10-2 to 10-6 Torr (102 to 104 millibar), akin to the conditions found in outer space. This procedure is typically performed at temperatures ranging from 50 to 500 Degrees C.

The object to be coated is then secured in a fixture and placed in the vacuum deposition chamber. The chamber is pumped down to the optimum pressure, depending on the coating materials, substrate and process requirements used, and the object to be coated is often preheated and plasma cleaned.

Why is Argon Gas Used for PVD?

Argon is classified as an inert gas, which means it possesses the physical and chemical properties of an element that does not react with other atoms or compounds in the atmosphere. This process ensures that the coating material remains pure when it enters the vapor phase in the vacuum chamber before being deposited on the substrate.

Furthermore, the introduction of reactive gases, such as nitrogen, oxygen, or acetylene, into the vacuum deposition chamber has been shown to yield compounds capable of establishing a remarkably robust bond between the coating and substrate during the deposition process. It is evident that thin film depositions can exhibit a thickness range extending from several angstroms to multiple microns. These depositions invariably result in the formation of an exceedingly adhesive coating, which has demonstrated its efficacy in a multitude of applications, including decorative finishes, electrical coatings, and a variety of other functional coatings. The potential applications of this technology are extensive.

The PVD coating process has been demonstrated to produce some of the most advanced and technologically sophisticated solutions of our era, including microchips and solar panels. A notable advantage of this process is its environmental sustainability, as it does not result in the generation of toxic byproducts that could potentially compromise the integrity of our planet’s environment.