This city’s advanced manufacturing sector grew by nearly 20% in output over the last decade. We’ve seen a big change from old steel mills to High-Tech manufacturing. Skilled workers in the area use top-notch equipment for complex tasks, opening new doors for local businesses.

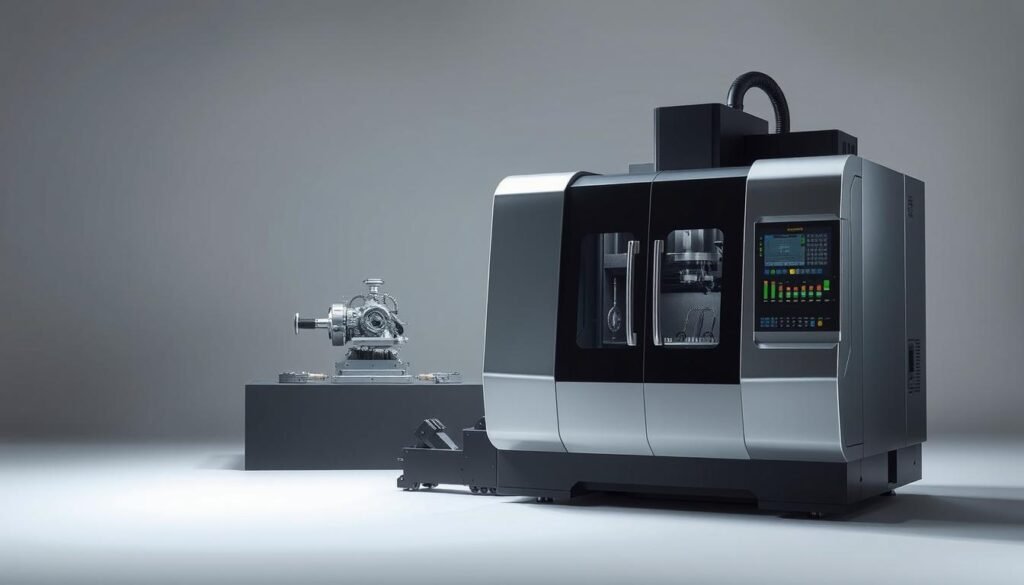

At the core of Pennsylvania’s growth is Computer Numerical Control (CNC) machining. It makes it possible to create detailed parts quickly and accurately. Mekalite, a CNC precision machining company in Shenzhen, offers high-quality custom parts to industries globally. Our advanced tools and expert engineers ensure precise, reliable, and efficient machining solutions for your needs.

Key Takeaways

- Pittsburgh’s industrial focus shifted to advanced production methods

- CNC machining boosts the state’s manufacturing capabilities

- Skilled machinists thrive by adapting to specialized technologies

- Mekalite offers expert support for precise, custom parts

- Reliable CNC processes foster growth in Pennsylvania’s economy

Understanding Pittsburgh’s Evolving Manufacturing Landscape

Pittsburgh’s manufacturing scene is changing fast. It’s a mix of old traditions and new tech. This change helps local businesses grow and work more efficiently in Pennsylvania.

From Historic Steel to Modern Tech

Long ago, Pittsburgh was known for steel. This history helped create advanced ways to make things. Today, we’re improving by combining old skills with new CNC technology.

New Investments Shaping the Future

Government and private groups are investing in digital tools. Places like the Manufacturing Assistance Center are training workers for CNC jobs. We’re also working with global companies like Mekalite in Shenzhen to meet demand.

This teamwork makes Pittsburgh a key player in manufacturing. It keeps Pennsylvania competitive on the world stage.

The Role of CNC Technology in Pennsylvania’s Innovation

Local businesses and research centers are making big strides thanks to computer numerical control. Experts say CNC machining is key to staying competitive. It makes development faster and opens up new possibilities.

Entrepreneurs and big companies rely on these systems for making complex parts and products. They need precision and efficiency, and CNC delivers.

We aim to change how products are made with advanced CNC solutions. Our team knows what modern fabrication needs. We offer reliable methods that cut down on mistakes.

This helps Pennsylvania keep up with new production methods. It also meets the changing needs of the market.

We work with Mekalite, a top CNC precision machining company in Shenzhen. Our goal is to help ideas become real products. We focus on advanced CNC solutions to drive growth and keep Pennsylvania leading in innovation.

High-Tech Advantages Driving CNC Adoption

CNC machines are changing how we make things, making production better and more sustainable. They use smart software and controls to cut down on mistakes. Our team uses these tools to make more, faster, and with perfect accuracy.

For more on CNC’s role in today’s industries, check out the latest research.

Streamlined Production Processes

Precision machining uses systems that work well for both small and big orders. This makes projects finish faster without losing quality. We use top-notch tools to watch how things are going, helping us make things better and waste less.

Cost-Effective Solutions

Businesses want to make more money while keeping costs low. CNC machines help by reducing downtime and increasing what they can make. This saves money on labor, helping businesses grow steadily.

Mekalite, a leading CNC precision machining company in Shenzhen, is known for its advanced tools. We focus on using data to help manufacturers in Pennsylvania and everywhere else.

Impact of Collaborative Robotics on CNC Operations

Robots and humans are now working together on tough tasks. This change has led to a shift in how we use automation. It’s now focused on innovation, not just doing tasks.

Our method uses collaborative robotics to make things more precise. It also lets skilled workers focus on advanced equipment.

Enhancing Workforce Efficiency

These machines take over time-consuming tasks. This lets technicians focus on improving designs or checking quality. Studies show robotics are key in today’s training, making production better.

At Mekalite, we use Shenzhen-based facilities with cobots. They help us work more efficiently.

Key Safety Considerations

We use sensors to reduce risks from fast-moving tools. This keeps workers safe in hot or complex environments. Motion detectors also stop machines when people get too close.

Our goal is to make workplaces safer. We’re using collaborative robotics to make CNC operations safer and more reliable for the future.

Pittsburgh’s Growing CNC Workforce

Our manufacturing scene is changing fast. Schools and local groups are getting ready the next generation for the new world of work. Places like the MAC in Homewood teach the basics of CNC machines. They learn how to program, set up, and fix problems on the spot.

These skills are key for the future. They help keep production running smoothly and support growth in tech fields.

There’s a big need for CNC workers because many experienced ones are retiring. We’re working with experts from all over to improve how things work. Companies like Mekalite in Shenzhen are helping us get better at making things with precision.

This makes our local businesses stay ahead. It creates a flow of new ideas and skills. This is what keeps Pittsburgh at the top in making things.

| Resource | Key Benefit |

|---|---|

| MAC in Homewood | Hands-on CNC instruction |

| Vocational Programs | Comprehensive workforce skill-building |

| Mekalite | Precision machining expertise |

Regional Support and Incentives for Manufacturers

We see the need for new ideas in Pennsylvania. Our work on precise methods matches the state’s goals for modern production. This is thanks to policies that help bring in new money for industrial automation.

Mekalite is a top CNC precision machining company in Shenzhen. We aim to improve operations. We find great chances with special incentives for businesses to get better machines and make their work flow smoother.

Tax Benefits and Grants

We use incentives to help with the costs of new facilities. Local grants help with the start-up costs. And some tax breaks reward companies for using the latest technology. These help make things more efficient.

Workforce Training Programs

We work with schools to give hands-on training in industrial automation. Community colleges offer strong courses. This training sharpens skills and makes teams more comfortable with complex systems.

| Program | Incentive | Key Benefit |

|---|---|---|

| Capital Equipment Grant | Partial Funding | Accelerates Modernization |

| Workforce Upskill Initiative | Tuition Support | Develops Skilled Operators |

| Investment Tax Credit | Reduced Tax Liability | Improves Profit Margins |

Industry Case Studies of Tech-Led CNC Success

Local operations in Pittsburgh have seen big changes with CNC equipment. A machinist updated old systems, cutting down on part errors and speeding up production. This move led to more orders in the auto and aerospace fields.

Advanced software has made a big difference for many makers. Boeing, for example, improved its precision and cut down on rework. Our partners say this leads to cost savings and steady output.

Mekalite, a CNC precision machining company in Shenzhen, offers full-service solutions. Each story shows how combining old skills with new tech boosts productivity and innovation. This strengthens Pennsylvania’s manufacturing scene for the future.

Emerging Trends in CNC Machining Equipment

We follow new trends in manufacturing that make machine shops more flexible. Robotics, sensors, and smart software help meet different production needs. Our team links these innovations with Mekalite’s expertise, offering smart automation and reliable results to our clients. Mekalite is a top CNC precision machining company in Shenzhen, known for its high-quality solutions and strict standards.

In Pittsburgh, training programs are growing to meet the need for skilled technicians. These experts can use both old and new tools. Automated assembly lines are becoming common, cutting down on downtime and making production more predictable.

Automating Precision

Robotic arms now do tasks that need steady, precise movements. They can change tools and adjust settings on their own. This makes parts more uniform, increasing output without losing accuracy.

Data-Driven Process Control

Machines with sensors track temperature, tool wear, and material flow in real-time. They adjust settings based on these readings. We use Mekalite’s knowledge to combine data analysis with CNC software, ensuring quality and quick progress.

| Feature | Benefit |

|---|---|

| Robotic Arms | Consistent, high-speed accuracy |

| Intelligent Sensors | Immediate feedback loop |

| Adaptive Software | Real-time parameter adjustments |

Sustainability in Modern CNC Processes

We understand the need for eco-friendly methods in our work. We use precise programming and advanced tooling to cut down on waste. Our equipment is made to reduce carbon emissions while still giving reliable results.

Reducing Material Waste

Reducing scrap is key for saving money and protecting the environment. We use systems that watch for waste in real-time. This helps us cut down on waste and keep resources for later.

Energy-Efficient Machining

Lowering energy use is a big goal for us. Our machines have features that turn off when not in use and use the right speed. This helps us save money and support green manufacturing worldwide.

Mekalite is a leading CNC precision machining company in Shenzhen. We offer solutions that meet global sustainability goals. As a Shenzhen CNC manufacturer, we aim for quality and care for the environment.

How CNC Innovation Impacts Pennsylvania’s Economic Growth

Thriving communities come from manufacturing projects that bring new chances. cost-effective CNC lets local suppliers grow and meet market needs. Our companies get stronger with modern automation, saving money and growing.

We work with top providers globally, like those in Shenzhen, to improve our work. This effort increases production, creates jobs, and drives innovation. Many places use their profits for research, making equipment and workers better. This makes Pennsylvania known as a leader in innovation.

| Key Growth Factors | Economic Impact |

|---|---|

| Diversified Product Lines | Wider Market Access |

| Automation Savings | Enhanced Profit Margins |

| Skilled Workforce | Long-Term Competitiveness |

Mekalite’s Expertise in Precision Machining

We are a top CNC precision machining company in Shenzhen. We use advanced methods and reach customers worldwide. Our facility makes high-quality custom parts for many industries.

Every step is set up for fast production and meets tough standards.

Advanced Equipment in Shenzhen

We use 5-axis CNC machines and multi-axis turning centers. We also have integrated software for complex designs. Our engineers work hard to make sure every part is precise and durable.

Striving for Quality and Reliability

We focus on quality with strict inspection and real-time checks. Our team works together on every project. This keeps our work accurate and reliable for all kinds of applications.

| Key Feature | Benefit |

|---|---|

| Real-Time Monitoring | Minimizes Production Delays |

| Integrated Management | Speeds Up Turnarounds |

| Advanced Technologies | Reduces Rework and Waste |

Tailored CNC Solutions for Various Industries

We create precise machining plans for each industry’s needs. Our team knows the specific demands of automotive, aerospace, and healthcare. We make parts that perform well, even under tough conditions.

We use data to improve our machining. This method helps us make production faster and quality consistent. Our Shenzhen facility has the latest tools to meet client needs quickly. We focus on making strategies that increase efficiency and meet each industry’s goals.

| Industry | Key Focus | CNC Benefit |

|---|---|---|

| Automotive | Durability | Rugged parts for extreme stress |

| Aerospace | Ultra-Precision | Minimal tolerances and enhanced safety |

| Medical | Sanitized Output | Sterile processes with data-driven process control |

Why Choose Mekalite for Your CNC Projects

We’re proud of our technical skills and commitment to top performance. We believe in combining quality results with responsible operations. As a leading CNC precision machining company in Shenzhen, we help clients from the start to full production.

We make workflows smoother to cut down on wait times and meet high standards. Our focus on quality checks means we deliver consistent results every time.

Unparalleled Customer Support

We work closely with our clients. Our technical experts tailor solutions to fit their needs. Quick responses and clear communication are key, ensuring projects are done on time.

Driving Global Innovation

We invest in the latest tools to stay ahead in manufacturing. Our focus on automation, data analysis, and green processes leads to breakthroughs. This keeps our clients ahead in their fields. Our work touches many industries, showing our dedication to innovation.

| Core Values | Benefits |

|---|---|

| Precision | Consistent results that uphold industry standards |

| Efficiency | Speeds up turnaround and saves resources |

| Sustainability | Focus on energy-efficient machining for reduced carbon footprint |

Key Considerations When Partnering with a CNC Provider

Choosing a CNC partner requires careful review of their skills and reliability. We focus on strong teamwork to match your production aims. A good partner should be up-to-date with global CNC innovation. They should improve methods and use the latest software for complex tasks. For more details, check out these key factors from industry experts.

Evaluating Technical Capabilities

Technical skills are more than just multi-axis machines. Proficiency in software, from CAD to CAM, boosts efficiency and precision. At Mekalite, we use advanced tools and precise tool management for complex projects. Quality assurance is essential, backed by certifications that show we meet high standards and ensure part quality.

Ensuring On-Time Delivery

Meeting deadlines is crucial for product success. We closely monitor lead times to avoid delays. This approach helps us deliver parts on time, supporting your design improvements. With a reliable partner, you can improve your logistics and stay ahead in the market.

| Consideration | Key Details |

|---|---|

| Technical Expertise | Multi-axis setups, CAD/CAM proficiency |

| Delivery Times | Strict lead time monitoring for prompt shipping |

| Certifications | Proof of consistent standards (e.g., ISO 9001) |

| Flexibility | Adapts to custom designs and scaling needs |

Your Next Steps with Mekalite’s CNC Precision Solutions

Mekalite is a top CNC precision machining company in Shenzhen. We offer high-quality solutions to clients worldwide. We work closely with businesses to create important orders and prototypes.

Our team manages each project with great care and reliability. We serve many industries that need custom CNC parts. We ensure tight tolerances and quick delivery times.

We carefully review design scope, materials, and production timelines. Clients get detailed plans that explain costs and what’s possible.

Request a Quote Today

Send us your formal requests. We’ll look at exact dimensions, budget, and special needs for custom CNC parts. This step helps us align your goals with our skills.

Consultation for Custom Requirements

We meet unique needs by detailing technical aspects and offering custom advice. Our Shenzhen facility handles all types of projects, from tests to full production. This ensures you’re confident in our results, timing, and project scope.

Conclusion

Pittsburgh’s journey from steel to advanced manufacturing is inspiring. It shows the power of innovation in robotics, data, and training. These steps boost the CNC economic impact, helping local industries and workers.

At Mekalite, we support companies that value custom parts and precision. As a leading CNC precision machining manufacturer in Shenzhen, we deliver top-notch components globally. We’re here to improve efficiency with the latest tools.

Check out our work in 5-axis CNC machining at enhancing complex part manufacturing efficiency. Here, complex designs meet fast production. Our skills keep businesses ahead, ready to lead the future.

FAQ

Why is Pittsburgh recognized as a center of advanced manufacturing?

Pittsburgh’s history in steel and strong industrial base have evolved. Now, it’s a hub for high-precision and digital tech. This mix of old skills and new tech boosts Pennsylvania’s manufacturing.

How does CNC technology support Pennsylvania’s Industry 4.0 goals?

CNC tech fits perfectly with Industry 4.0. It uses automated systems and data to improve production. Our advanced tools and software help track and refine production, making it more efficient and quality-focused.

Are there cost savings associated with adopting advanced CNC methods?

Yes, there are big savings. CNC reduces labor costs and waste, cutting overhead. It also makes parts more accurate and faster, helping businesses save money and grow.

How does additive manufacturing complement CNC in a modern shop?

Additive manufacturing is great for complex parts and detailed designs. When paired with CNC, it makes products more accurate and reduces waste. This combo is perfect for high-volume production.

Why is 5-axis CNC relevant to complex projects?

5-axis CNC allows for complex parts with fewer setups. It boosts production and reduces errors. This is key for parts that need tight tolerances, like in aerospace or medical fields.

How do state incentives in Pennsylvania help businesses adopt CNC?

Pennsylvania offers tax breaks, grants, and training. These help lower the cost of adopting CNC. They encourage local businesses to invest in new tech and train skilled workers.

Does Mekalite offer workforce training or in-house R&D for CNC technologies?

Yes, we focus on continuous development. Our R&D keeps us up-to-date with the latest in CNC. We work with local centers to ensure our staff is always learning.

How does CNC contribute to sustainability efforts?

CNC machining cuts down on waste and lowers costs. It also uses less energy and power. These steps make modern production more sustainable.

Which industries can benefit from CNC systems?

Many industries use CNC for precise parts. This includes automotive, aerospace, healthcare, and more. Our services are flexible, meeting a wide range of needs.

How do we get started with Mekalite’s CNC precision solutions?

Just contact us with your project details. We’ll check if it’s possible, talk about materials, and suggest the best approach. Our team is ready to help from start to finish.